Semi-Automatic Filling Machines

Semi-Automatic bottle and liquid Filling Machines. ISO certified solutions for volumetric filling of liquids into bottles, jars, tubes, & more.

Filter By Product Specifics:

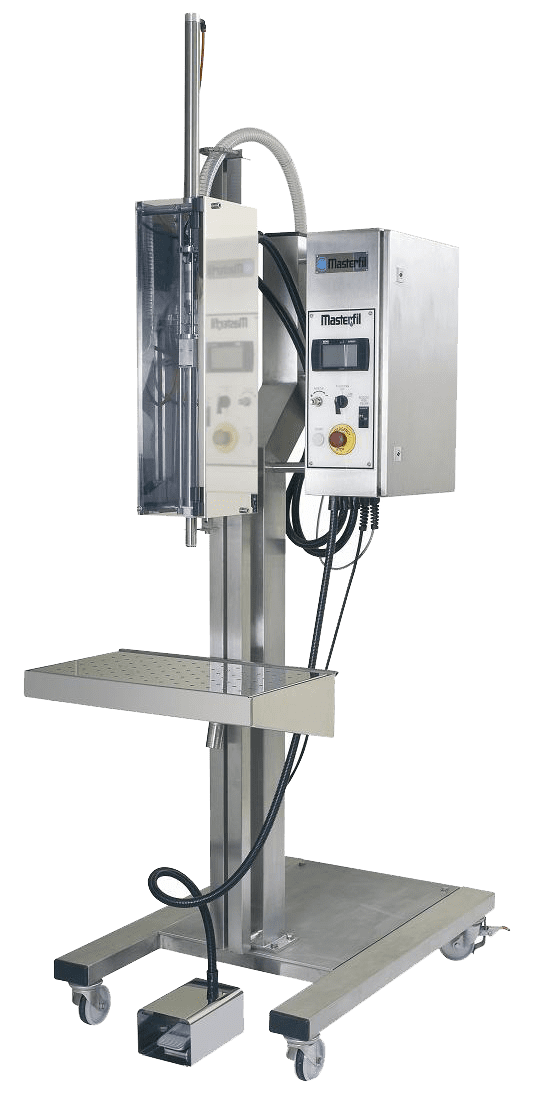

Masterfil Semi-Automatic Volumetric Filler

A semi-automatic volumetric filling machine, ideal for small batch production, up to 720/h

Masterfil Semi-Automatic Flowmeter Filler

A semi-automatic flowmeter filling machine, ideal for those that require fast product changeover and want to minimise the use of cleaning fluids

Masterfil Bench Height Weigh Scale Filler

A semi-automatic weigh scale filling machine, ideal for those that require fast product changeover and want to minimise the use of cleaning fluids

Response Benchtop Filler

Versatile, hygienic and easy to use, the Response Benchtop Filler was developed in response to our customers’ requests, hence the name!

ATEX Response Benchtop Filler

CAT II 2 G c T 5 (100 Degrees Celsius) Response Benchtop filling machine

XYZ Distributor

A semi-automatic peristaltic filling machine, for filling bottles, vials and nested syringes

Accuramatic Peristaltic Dispensing Unit

Quick, easy, and hygienic filling of bottles, vials, ampoules or nested syringes. Can be paired with our XYZ Distributor or Ampoule Filling Jig.

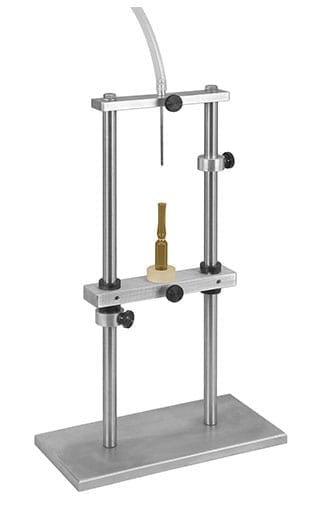

Ampoule Filling Jig

A useful hand-operated accessory to ensure clean filling of small necked containers such as ampoules, without wetting the wall where it is to be sealed

TGM E250Semi Tube Filler & Sealer

A semi-automatic tube filling and sealing machine for metal, polyethylene and laminate tubes, up to 2,500/h

Semi-Automatic Liquid Filling Machinery

Semi-Automatic Filling Machines are most loved by small to medium scale productions, but larger businesses will also invest in the trusted solution especially for samples, R&D projects and seasonal products.

The operator uses a foot pedal trigger filler; semi-automatic means that you still have control over the filling speeds. The operator also has to place containers under the filling heads as there are no conveyors.

Browse our range of semi-automatic liquid filling machines.

Adelphi Semi-Automatic Liquid Filling Machines

Adelphi Masterfil and Adelphi Manufacturing offer Semi-Automatic Liquid Filling Machines to accommodate customer needs.

Adelphi Masterfil offer volumetric, flowmeter and weigh-scale filling options ranging from sizes 200ml to 5L (potentially higher at 30L with multi-shot). All of our semi-automatic filling machines can be specified with one or two filling heads, single or acting product cylinders and a remote nozzle for filling containers on pallets. Can be configured for use in ATEX Zone 1 Category IIB 2G c T4 (135C).

Download a technical brochure.

Streamlined Filling Solutions

Adelphi Manufacturing offer various semi-automatic liquid filling machines including the Response Benchtop Filler. A range of interchangeable nozzles are available for different products, including liquids, oils, gels, creams, pastes and thick products with particulates. Can be configured for use in ATEX Zone 1 Category IIB 2G c T4 (135C).

Adelphi Manufacturing also offer their XYZ Distributor which can be combined with the Accuramatic Peristaltic Dispensing Unit – ideal for filling bottles, vials and nested syringes the XYZ has an exceptional filling accuracy of up to +/-0.5% reduces costly product waste.

Types of Semi-Automatic Filling Machines

As mentioned, Adelphi Masterfil provide different types of filling machinery, here’s what you should know about each type:

Volumetric

- Uses product cylinders to accurately fill

- Twin-head options to increase throughput

- Professional quality sensors are included throughout the conveyor to prevent container waste; the neck location sensors will align bottles with filling nozzles and the machine won’t fill if the incorrect amount of containers are sensed

- A gating system is also in place to hold containers while they are filled to ensure the containers do not move and there are no damages or breaks

Flowmeter

- No pistons for a reduced wash time for a faster product and container changeover

- Product volume is weighed as the filling takes place, there are also options of feedback from the checkweigher to auto-adjust flowmeter via software interface

- Exceptional filling accuracy of ± 0.2% significantly improves your ROI

Weigh Scale

- No pistons for a faster changeover between different products and container types

- No need for fully purged lines, meaning you never waste product on initial set up

- Produces up to 720 containers per hour; producing up to 5,760 containers per 8 hour shift

Explore our range of Semi-Automatic Liquid Filling Machines

Browse our full range of semi-automatic liquid filling machines. You can filter by container type and size to find the perfect solution for you.

If you would like to receive expert advice on the best filling machine for your business, contact us using the form below

“We like working with people we can trust. Adelphi have been with us since day one – without them we couldn’t have done it! ”

- Chris Taylor – Eve Taylor (London) Ltd

“Extremely friendly and accommodating team who went above and beyond expectations to deliver a high quality end product. Also visited their manufacturing facility which was of a very high standard. Will definitely work with Adelphi in the future. ”

- Brian Barry – Technopath

“I just wanted to thank you for all you did, Adelphi went above and beyond to help! My team are really excited about this new venture. Again, thank you! ”

- Eleanor Wade – O&3