Spares & Format Parts

The Adelphi Group of Companies offers a cost-effective and timely spares and format parts service. We provide filling machine spare parts for complete after-sale peace of mind, wherever you are in the world.

Filling Machine Spare Parts

In the event that you require spare or format parts for your Adelphi machinery, you can be confident that we will be here to support you.

We carry all common machine spare parts in stock and usually dispatch within forty eight hours to minimise your production downtime.

Format parts are often required when introducing a new container or cap to your range. All format machine parts are designed and manufactured to order due to their bespoke nature, however delivery can usually be expected within five weeks of our receipt of your samples.

In need of spares or format parts?

Contact us using the form below…

Enquire about spares & format parts

Spare Parts for Filling Machines

All of the Adelphi Group companies hold in stock – or can quickly source – a range of spare machine parts for all of equipment. For example:

- Adelphi Manufacturing offers spare parts for their range of laboratory equipment, as well as filling machine spare parts.

• Bulbs for the Apollo range are available from stock for quick delivery within days

• Tubing for the Peristaltic Dispensing Unit and XYZ Distributor

• Seals, cup washers and O-rings for the Response Benchtop Filler

Adelphi Masterfil also have a range of spares available for their liquid filling and capping machinery including O-ring seals, ball seals and bearings.

Pharma Hygiene Products offers the best of British and European quality in their range of hygienic tri-clamp fittings. Constructed from 316L pharmaceutical grade stainless steel, you are guaranteed the highest quality and a durable product.

“Thanks to your swift and valuable response, we are now back in production!”

Total Kenya Ltd

Liquid Filling Machine Spare Parts

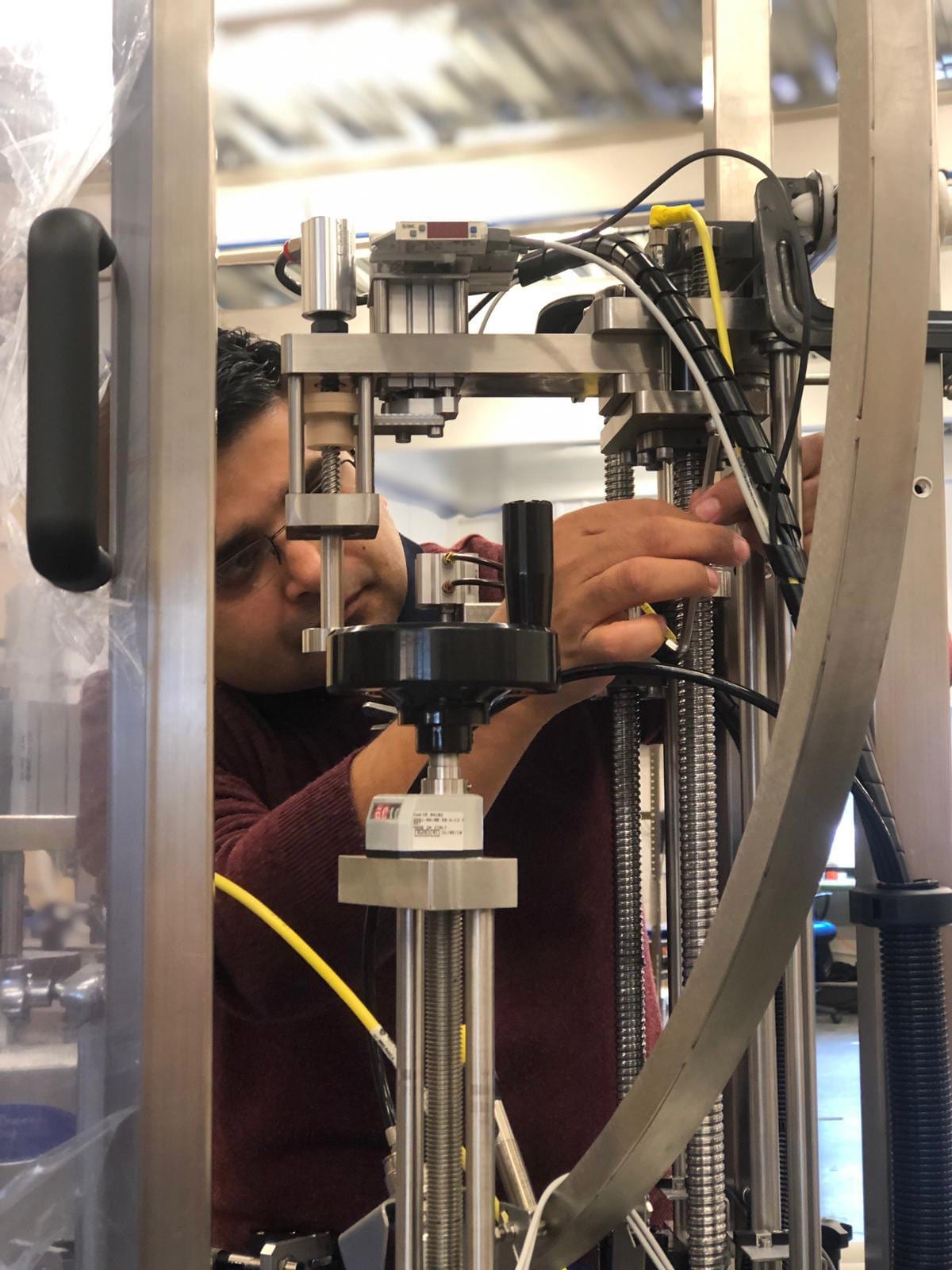

The highest use parts on a liquid filling machine can wear down over time, so you may be required to change these parts. We have a team of highly experience engineers to offer support with liquid filling machine spare parts and repairs. Find out more about our machine servicing.

Experiencing a breakdown can cost your company time and money, so at Adelphi we want to prevent this at all costs! Having a backup supply of critical spare parts is suggested, to protect against worldwide shortages and minimise any downtime you may experience.

So which backup parts should you keep on site? For liquid filling machines, the most common working part to need replacing is seals; this includes O-ring seals and ball seals. If you are unsure of which parts you should have in stock for your specific machine, contact us using the form above to request advice from an industry expert.

Seals kits are available for some of our machines including the Response Benchtop Filler; this kit gives you the spare parts most commonly required for that machine. The Response Benchtop Filler Spares Pack includes:

- Cup washers to suit your pump size

- O-Rings for pump, nozzle and valve

- Stainless steel bearings

- Tri-clover clamp and seal

- Hex Key to strip down the machine

To request your Spares Pack, simply use the contact form above and a member of our team will be able to assist you.

Capping Machine Spare Parts

To keep your capping machine running like clockwork, regular maintenance and a supply of spare parts on site are necessary. Ignoring minor maintenance and only purchasing spare parts when they are needed could result in a machine breakdown and cost your business money.

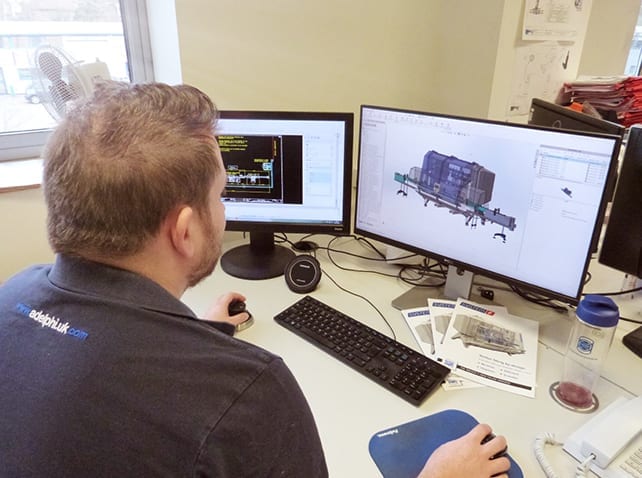

Despite our capping machines being of the highest quality, over time you are likely to experience some wear, due to the constant use of a machine. The best way to use your time and money effectively is to understand your machine as well as possible. Capping Machine spare parts can be placed into 3 categories: high wear, medium wear and low wear parts.

High wear parts are those with a short lifespan which will need replacing most regularly. Due to their demand you may find these parts have a long lead-time, so make sure to stock up! Buying knock-off parts on a short lead-time is false economy, as they will not perform as required, and you can find yourself needing to replace them even sooner.

Medium wear parts have a longer lifespan than high wear, but you still may see them deteriorate and require replacing, so you should keep an eye on these during your routine maintenance.

Low wear parts are those made of the most durable material. It is not guaranteed but it is highly likely that your machine can go its lifetime without needing to replace these parts.

Now you understand which category your parts fall into, you can manage your stock levels and have enough capping machine spare parts to hand. If you need further support, don’t hesitate to get in touch – Adelphi are here to offer our knowledge and assist our customers.

Find Spare Machinery Parts with Adelphi

Want to request a spare parts quotation?

Unsure of what parts you should have on stock and would like to speak to an expert?

Need to book in your annual service?

Contact us using the form below and our team will get back to you.