Vial Processing

Vial Filling, crimping and inspection solutions, from benchtop to fully automated vial processing machinery.

Filter By Product Specifics:

Response Benchtop Filler

Versatile, hygienic and easy to use, the Response Benchtop Filler was developed in response to our customers’ requests, hence the name!

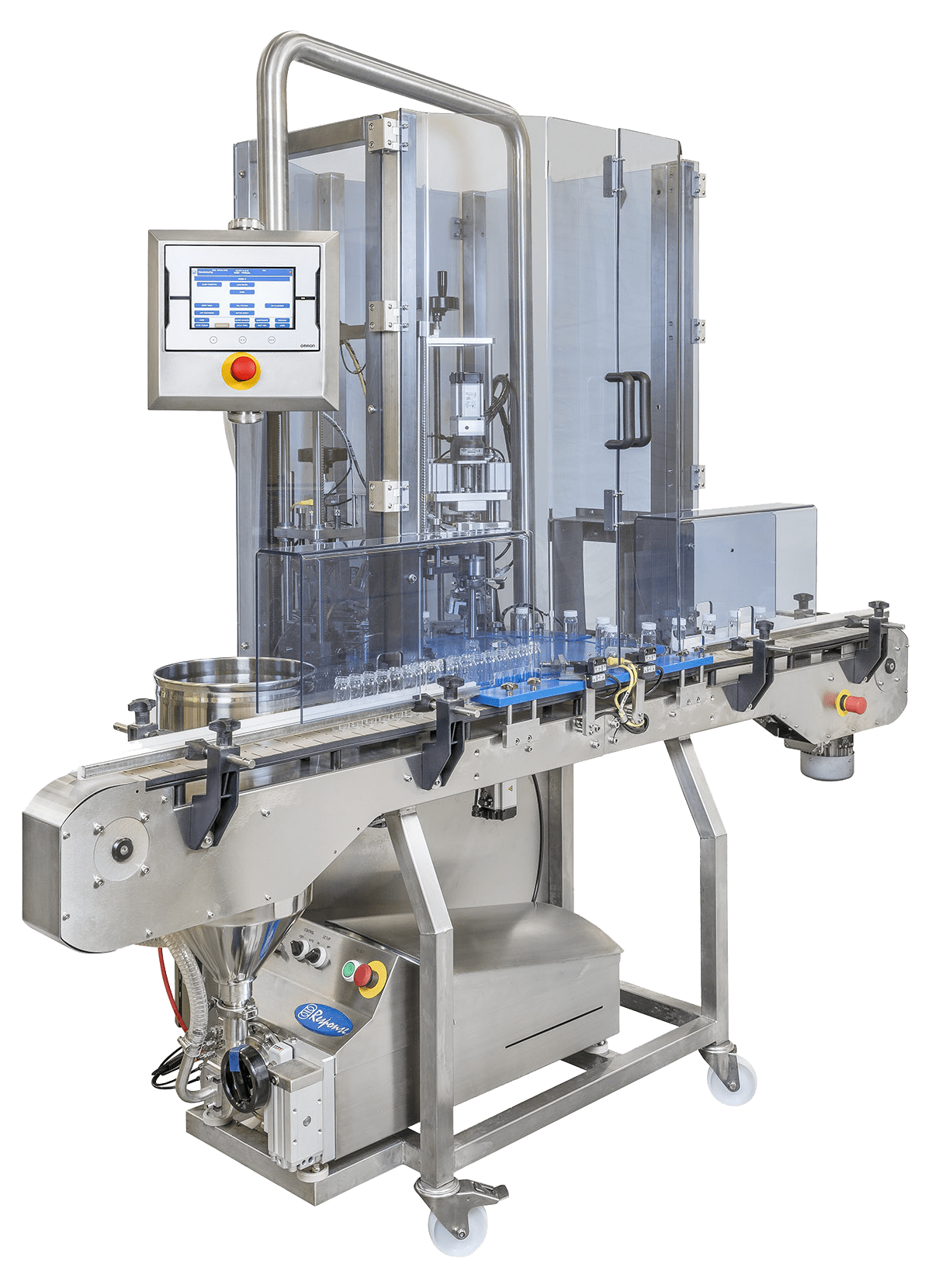

Response Monobloc 250 Filler & Capper

An automatic Monoblock style filler and capper, which provides many advantages for customers compared with traditional inline packaging systems

XYZ Distributor

A semi-automatic peristaltic filling machine, for filling bottles, vials and nested syringes

Accuramatic Peristaltic Dispensing Unit

Quick, easy, and hygienic filling of bottles, vials, ampoules or nested syringes. Can be paired with our XYZ Distributor or Ampoule Filling Jig.

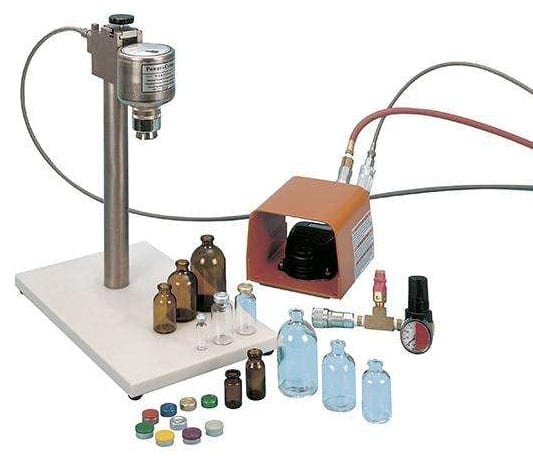

Powered Vial Crimper

Fast and reliable semi-automatic crimping or de-capping of vials ranging in size from 8mm to 32mm

Manual Vial Crimper

A durable and efficient manually operated benchtop crimping machine, for 8mm to 32mm vials

Vial Crimping & De-Capping Tongs

A range of high quality tongs and pliers for the crimping and de-capping of pharmaceutical vials

Bottle / Vial / Syringe / Test Tube Washer

Versatile and efficient washer for bottles, vials, syringes and/or test tubes, up to 900/h

Apollo I Liquid Inspection Unit

A polarised inspection light with 1.7x magnification, for the detection of particulate matter in transparent liquids contained in ampoules, vials and bottles

Apollo II Liquid Inspection Unit

The Apollo II Liquid Viewer provides a simple method for the detection of visible particles in transparent glass ampoules, vials, and bottles. European Pharmacopoeia Specification 2.9.20 & US Pharmacopoeia USP chapter 41, section 6.1 compliant

Apollo II Dimmable Liquid Viewer

The Apollo II Dimmable Liquid Viewer provides a simple method for the detection of visible particles in transparent glass ampoules, vials, and bottles. Light level between 1,200 and 3,500 Lux: Light level is adjustable by dimmer control, depending on the light in the room

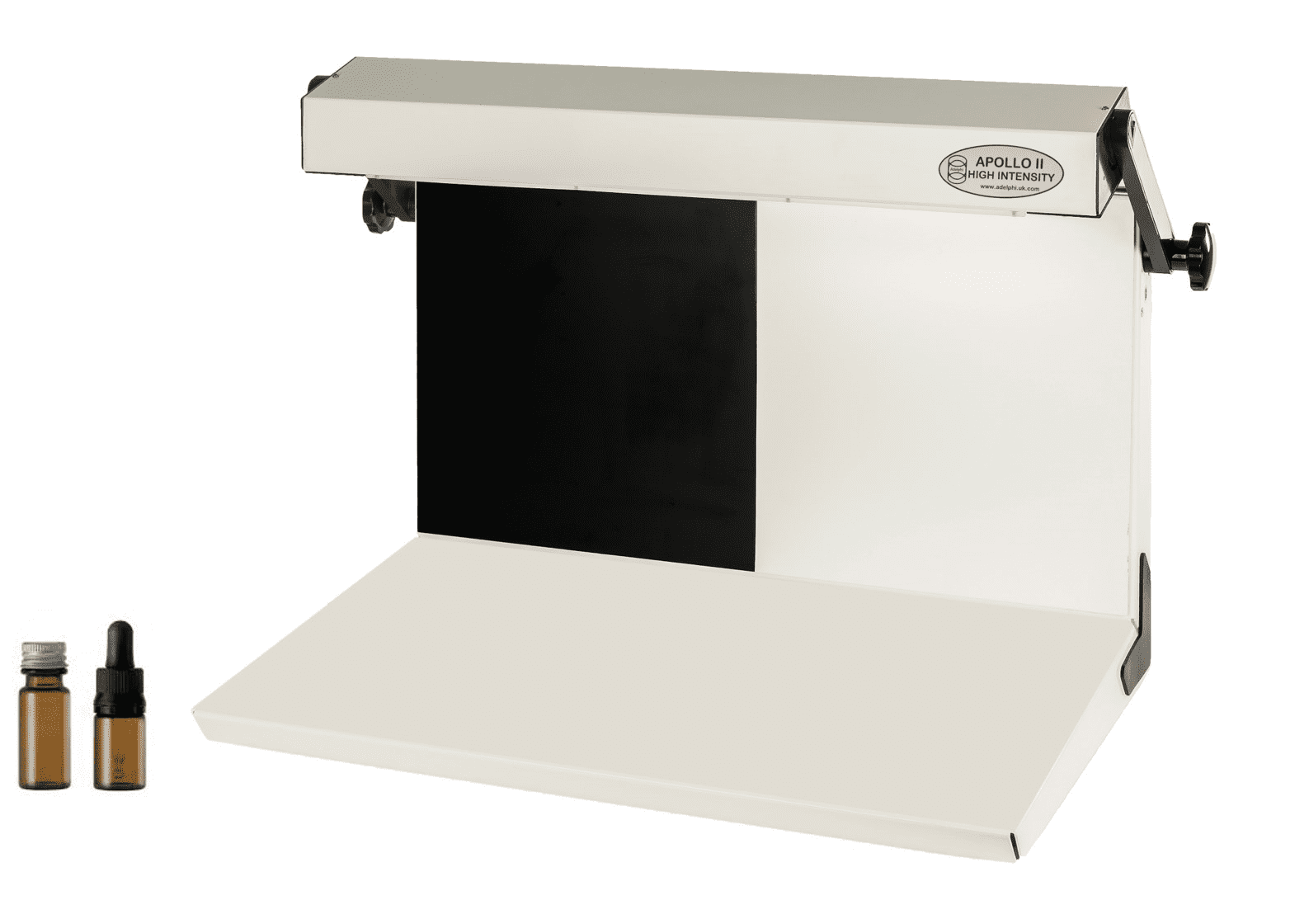

Apollo II High Intensity Liquid Inspection Unit

The Apollo II High Intensity Liquid Viewer provides a simple method for the detection of visible particles in transparent and coloured glass ampoules, vials, and bottles. Light level between 8,000 and 10,000 Lux, specifically for coloured glass containers

ROTA FLR50 Vial Filler & Closer

A versatile and compact solution for the automatic filling and closing of vials, up to 3,000/h

ROTA FLR100 Vial Filler & Closer

A compact solution for the automatic filling and closing of vials, ideal for small batch production, up to 6,000/h

ROTA FLR150 Vial Filler and Closer

A compact solution for the automatic filling and closing of vials, ideal for small batch production, up to 9,000/h

“We like working with people we can trust. Adelphi have been with us since day one – without them we couldn’t have done it! ”

- Chris Taylor – Eve Taylor (London) Ltd

“Extremely friendly and accommodating team who went above and beyond expectations to deliver a high quality end product. Also visited their manufacturing facility which was of a very high standard. Will definitely work with Adelphi in the future. ”

- Brian Barry – Technopath

“I just wanted to thank you for all you did, Adelphi went above and beyond to help! My team are really excited about this new venture. Again, thank you! ”

- Eleanor Wade – O&3