SAT & FAT Testing

Guarantee that your equipment fulfils your production requirements

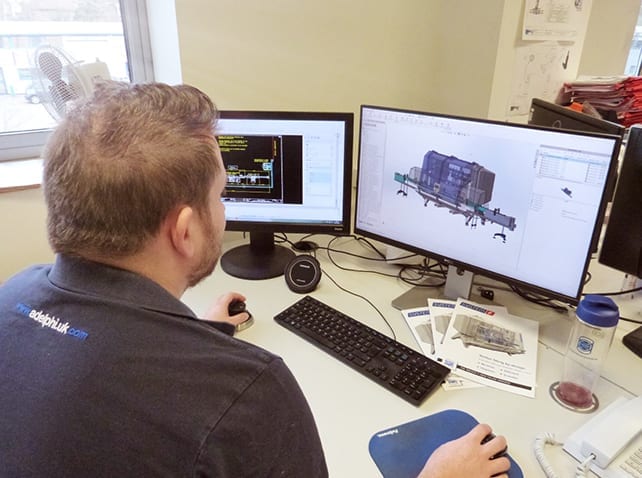

Factory Acceptance Testing

The Factory Acceptance Test, which is traditionally in the presence of a customer representative (although now commonly pre-recorded or via live video link) serves to take a customer through the overall build quality, health and safety requirements, functionality, control and accuracy of their equipment to ensure it meets their requirements and expectations prior to despatch. A customised FAT document is used as a guide and to formalise the process whilst the machinery is tested within our facility. FAT Testing is always recommended to familiarise customers with the equipment, and of course quiz our highly experienced production technicians prior to receiving it on site.

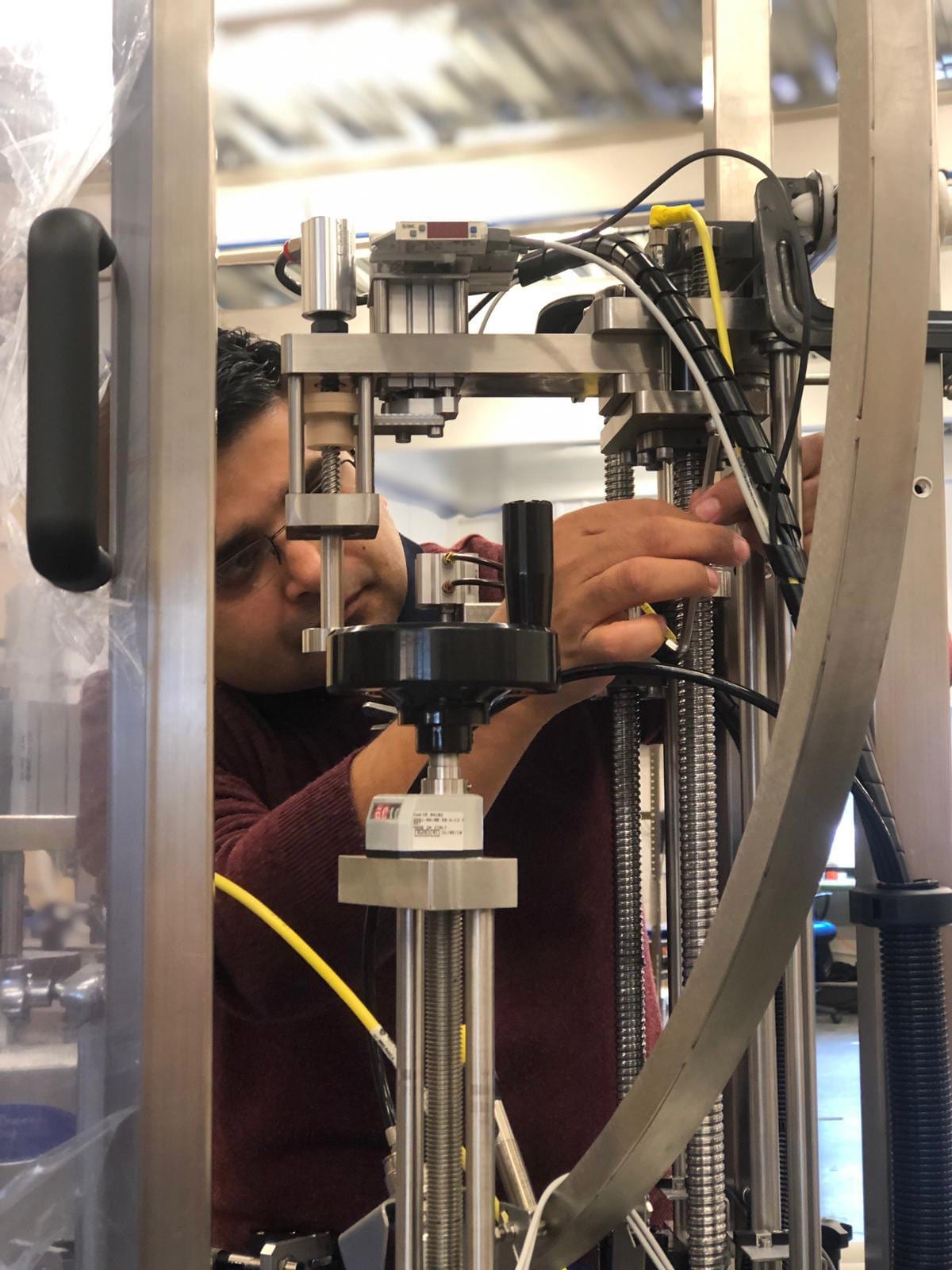

Site Acceptance Testing

The Site Acceptance Test is similarly used to ensure the equipment, once commissioned on a customer site, meets the requirements and expectations within the working environment and with the complete product range.

Machinery Training

Adelphi provides full training for all our equipment and machinery, for novice learners, experienced operators and supervisors.

“Very good indeed at what they do.

We trust Adelphi’s specialist engineers.”

Kilco International