News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

Vials: From Precision Filling to Final Inspection

May 14, 2025

Introduction:

You already know that sourcing high-quality vials is essential for product integrity. However, this is also true for your lab equipment, which protects the vial encasing your drug.

Three technologies by Adelphi Manufacturing can play pivotal roles in your vial’s journey: the XYZ Distributor, the Powered Vial Crimper and Apollo II Liquid Inspection Unit. All together, they support streamlined production and stringent quality assurance.

Did You Know…

Our sister company Adelphi Healthcare Packaging can support you if you require a supply of vials, both sterile and non-sterile.

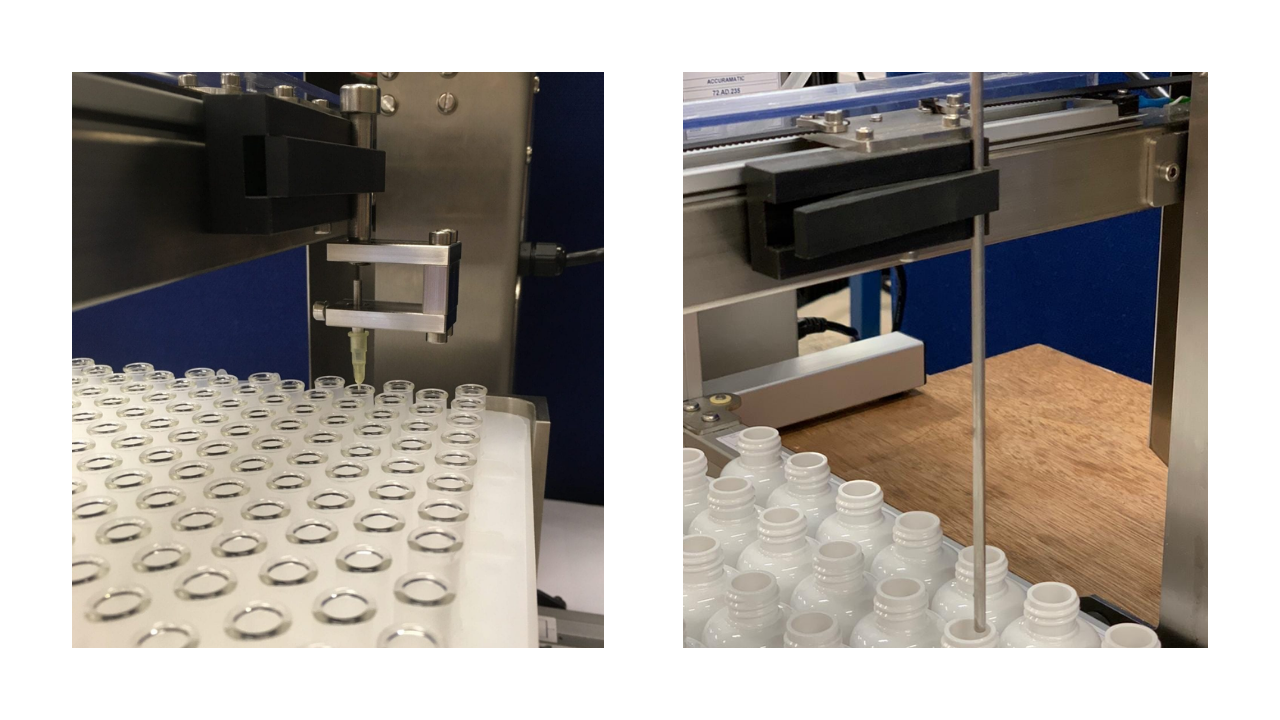

Precision Vial Filling with the XYZ Distributor:

The XYZ Distributor has been engineered for extremely accurate dosage, for applications ranging from research to mid-scale manufacturing. Designed to handle various container types, including crimp-necked glass injection vials, it offers you programmable control, speed, and nozzle positioning.

Its intuitive interface and repeatable accuracy support your compliance with GMP standards, reducing risk of overfilling and underfilling. Whether you’re working with viscous biotech formulations or aqueous diagnostic reagents, the XYZ Distributor supports cleanroom workflow.

Secure Sealing with the Powered Vial Crimper:

Sealing is the next step for ensuring product integrity. Designed for a variety of seals, including ‘plain’, ‘flip top/flip off’ and ‘flip tear up’, this unit delivers repeatable crimping and uniform seal quality across batches. Suitable for both crimping and de-capping, the Powered Vial Crimper streamlines final stage production and helps safeguard sterility and container closure integrity.

Product Quality with the Apollo II Liquid Inspection Unit:

Our Apollo II Liquid Inspection Unit serves as the final quality gate, providing rapid and repeatable visual inspection for particulate matter.

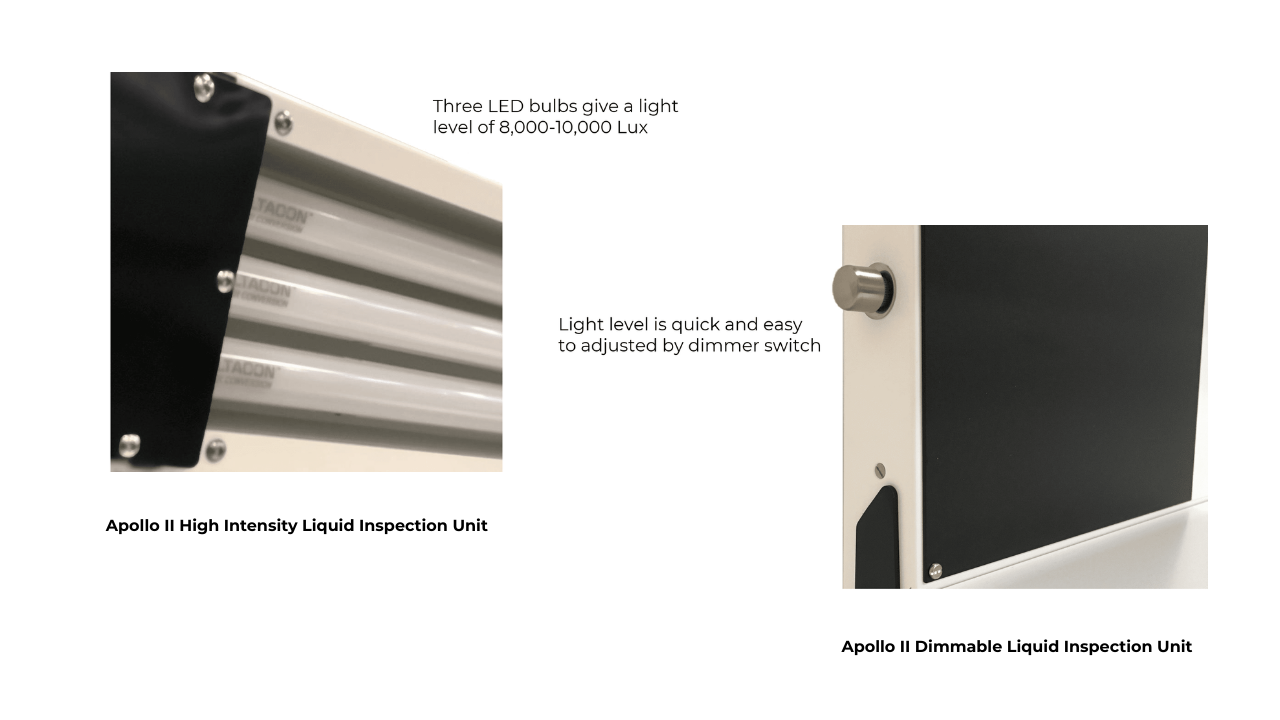

Apollo II High Intensity Liquid Viewer: Ideal for inspecting products in amber glass containers. It utilises three LED bulbs to provide a light level of 8,000–10,000 lux, facilitating the detection of particulate contamination in challenging products such as opalescent, coloured, or opaque solutions, as well as lyophilisates.

Apollo II Dimmable Liquid Viewer: Offering adjustable light levels between 1,200 and 3,500 lux via dimmer control, this unit allows customisation based on ambient lighting conditions. This version of the Apollo II allows for particulate detection for drugs which are photosensitive.

The standard Apollo II model as well as the Apollo II High Intensity conform to European Pharmacopoeia Specification.

Serving a Global and Diverse Industry:

From biotech start-ups, to diagnostic labs, to pharmaceutical CMOs, the demand for reliable equipment is universal.

By investing in the XYZ Distributor, Apollo II and Powered Vial Crimper you can confidently process delicate or reactive formulations, maintain batch integrity, and adapt quickly to production needs, whether in early-stage development or high-throughput commercial runs.