News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

Beyond the Price Tag: Scalable Equipment for Long-Term Cost Control

May 28, 2025

Financial resilience for CMOs is under dual pressure: to deliver competitive pricing to brand owners, whilst absorbing rising costs from materials, labour, utilities, and equipment. And all the while, traditional cost-cutting is reaching its limits.

Below are just some of the unpredictable costs which CMOs can face:

- Component shortages can lead to expensive delays or substitutions

- Unplanned downtime can inflate labour and spoilage costs

- Energy and utility prices can erode margins

- Market fluctuations may force production line changes on short notice

These variables impact cost-to-produce, margins, and scheduling, and are increasingly out of CMOs’ direct control.

However, strong relationships with strategic partners can reduce these uncertainties, by embedding flexibility, durability, and predictability into your capital investments.

Filling Machinery as a Tool for Cost Mitigation

The right filling solution does more than move product – it acts as a buffer against cost spikes, downtime, and inefficiencies.

A well-chosen automation option can provide:

- Lower total energy consumption per production run

- Faster format changeovers to reduce idle time and labour hours

- Modular design that allows incremental upgrades instead of costly overhauls

- High fill accuracy, minimizing product waste and rework

- Shorter cleaning cycles that cut water use and increase uptime

- Longer equipment lifecycle, which reduces replacement cycles and CAPEX burden

The Response filling machine range from Adelphi Manufacturing supports CMOs in each of these regards. From fast filling (up to 40 containers per minute) and exceptional accuracy (up to ±0.25%), to the ability to fully strip for cleaning in as little as 3 minutes – many of these machines are still fully operational over 30 years after installation!

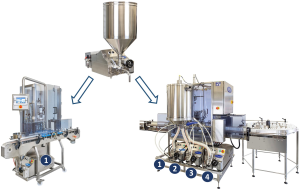

The range includes a Benchtop Filler, which can be integrated into either a Monobloc Filler/Capper or an inline Automation Base, as output demands increase. You can also separate out your benchtop machines again, for maximum flexibility, to fulfil multiple requirements at once.

This can also be an advantage if an unexpected request or order comes in, or to fill samples, pilots or tightly controlled batches of high value products.

In short, intelligent automation pays for itself – not just in throughput, but in long-term cost avoidance and operational flexibility.

“The cheapest machine today might be the most expensive decision tomorrow”

Too often, capital equipment (CapEx) purchase decisions are based purely or primarily on initial cost.

A more holistic approach includes evaluating Total Cost of Ownership (TCO) in real terms:

- Energy and utility running costs over expected machine lifetime

- Maintenance frequency and spare parts availability

- Training and support availability and cost

- Upgrade flexibility potential as your customers’ needs evolve

A strategic partner gives contract manufacturers TCO clarity, and helps manage financial performance over the life of the equipment. A partner who helps you model and manage total cost of ownership (TCO) is delivering more than machinery – they’re delivering predictability and stability.

Building Financial Resilience Through Partnership

It is incredibly important for CMOs to work with partners who stay invested after the PO is signed; who share a commitment to your operational and financial success, and who can provide upfront visibility of longer-term operating costs.

After all – it’s not the lowest price that wins—it’s the highest value, delivered consistently.

Find out more about the proven Response range of filling machinery for CMOs, and/or consult with our dedicated team today: +44(0)1444 472300 info@adelphi.uk.com