News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

Application Case Study

June 18, 2025

Application Case Study:

Adelphi Masterfil Automatic Volumetric Filler

Industry: Ready Meals & Convenience Foods

Application: Hot-fill of thick, particulate-rich Bolognese sauce

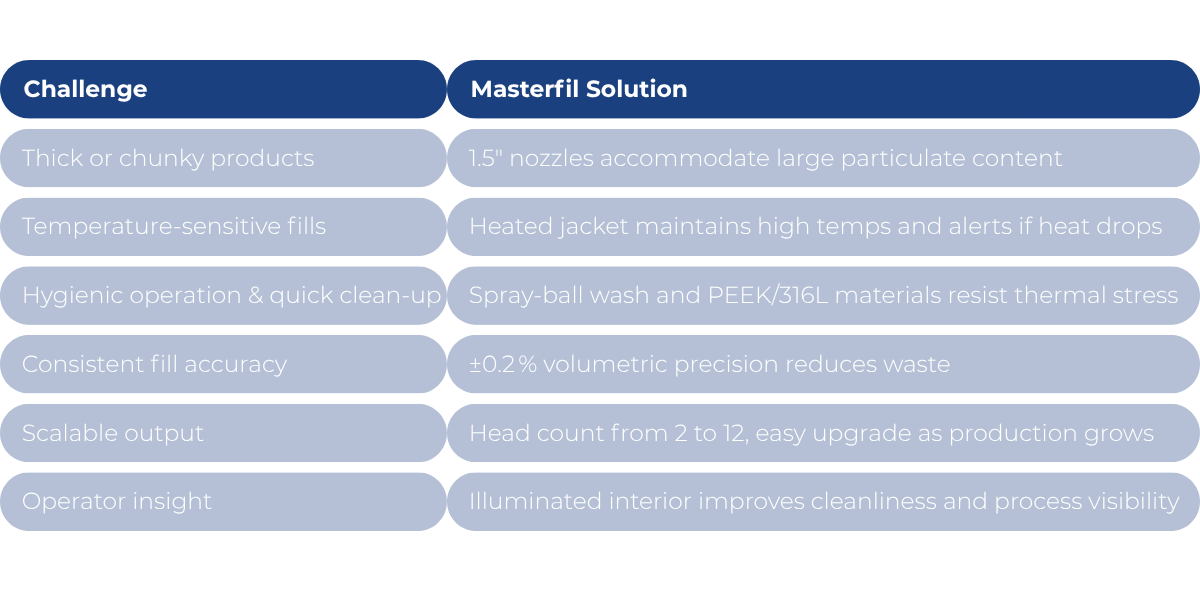

The Challenge: The manufacturer outlined several key production hurdles:

- Handling a Chunky, High Viscosity Filling: Traditional nozzles clogged or restricted flow of thick, particulate-rich Bolognese sauce.

- Hot-Fill Requirements: Maintaining sauce at a high temperature was essential for shelf stability and food safety.

- Hygiene Standards: Downtime for lengthy cleaning between batches can significantly impair productivity.

- Fill Accuracy: Inconsistent volumes can lead to overfill waste and compliance risk.

- Scalability: The system needed to grow with future production demands.

- Operational Visibility: Operators required better process insight and contamination prevention.

The Solution: The Adelphi Masterfil S5000-A Volumetric Filling Machine

The S5000-A Automatic Volumetric Filler from Adelphi Masterfil is engineered to deliver fast, accurate and hygienic filling for a wide variety of products from sauces and creams to oils and industrial fluids. With a capacity of up to 4,500 containers per hour, it offers high-speed productivity combined with exceptional filling accuracy of ±0.2 %, reducing both product and container waste.

Bespoke Heated Jacketed Tank – Keeping Products at Food-Safe Temperatures

Thick and high viscosity products sauces lose heat quickly, and if not properly insulated/heated, may fall below safe fill temperatures, risking microbial growth, spoilage or shelf-life failure in hot-fill processes.

A bespoke jacketed tank was created for this customer’s S5000-A Automatic Volumetric Filler, which is capable of maintaining product temperatures up to 95 °C. This ensures temperature-sensitive products like sauces or fats stay at a safe temperature and maintain optimal consistency during production.

Intelligent Temperature Control – Enhanced Safety

An integrated temperature monitoring system actively adjusts fill volumes to maintain the set temperature. If a product enters the system at too low a temperature, the S5000-A automatically detects this deviation from the expected pre-heated level.

The system is pre-programmed with target temperature parameters, and will immediately trigger warning alerts if a product hasn’t reached the required heat. To prevent under-heated or potentially contaminated product from being dispensed, the machine can automatically empty the tank, ensuring that no substandard fill passes through the system. This proactive safeguard protects product integrity and ensures compliance with food safety standards.

Extra-Large Depositor Nozzles to Prevent Flow Restrictions and Nozzle Clogging

Standard nozzles often clog or restrict flow when high viscosity filling takes place. Thick sauces or chunky product filling can then lead to inconsistent fills, downtime or damage to product integrity.

The S5000-A can successfully fill high viscosity, thick and chunky sauces using 1.5″ diameter automatic depositor nozzles. These oversized nozzles, along with a matching body and inlet adaptor, prevent blockages and ensure smooth, consistent filling.

While not interchangeable with smaller quick-release nozzles, they are available as an upgrade kit, allowing manufacturers to switch to chunky product filling when needed.

Premium Food-Grade Seals & PEEK Components

Frequent exposure to the higher temperatures and more aggressive cleaning chemicals required in food manufacturing, can degrade standard filler components, leading to leaks, contamination risk and costly downtime from frequent replacements.

All wetted parts on the S5000-A feature food-grade seals, enhanced by PEEK (Polyether Ether Ketone) polymer components, a high-performance engineering plastic known for exceptional mechanical strength, thermal stability and chemical resistance. Designed for washdown environments and fill high temperatures, PEEK’s durability ensures a longer component lifespan and reduces the need for frequent replacements.

Tank Washing System

Manual cleaning between product runs is time-consuming, labour-intensive and increases the risk of contamination due to inconsistent sanitation.

The S5000-A filler’s tank includes an automated CIP (Clean‑In‑Place) system that uses spray balls to distribute high-pressure water throughout the interior, effectively flushing out residues between runs. This efficient, easy-to-use washdown feature significantly reduces cleanup time and ensures consistent sanitary conditions for food-safe production.

Illuminated Interior for Greater Visibility

Poor visibility inside filling equipment can cause operators to miss signs of contamination risk, residue build-up, or incomplete cleaning, which can compromise product safety and increasing maintenance time.

The S5000-A filler includes bright internal lighting that enhances visibility inside the tank and around the nozzles. This illumination allows operators to easily detect early contamination or build-up and supports thorough inspection during cleaning processes.

Key Technical Highlights

- Fill volumes range from 250 ml to 30 L

- Choose between 2 to 12 filling heads, scalable as production grows

- Durable 316L stainless steel and PTFE wetted parts with standard Viton seals

- Optional dive/rise nozzle programming to prevent foam or splash

- “No container, no fill” sensor safeguards product and container integrity

- PLC-controlled with recipe-driven HMI and storage of fill profiles for quick changeovers

Key Benefits for Food & Beverage Manufacturers

The Adelphi Masterfil S5000-A Volumetric Filling Machine proved to be the ideal solution for the complex task of hot-filling thick, chunky Bolognese sauce. With its hygienic design, modular scalability and industry-leading precision, it enabled the manufacturer to meet both current production needs and future growth goals.