News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

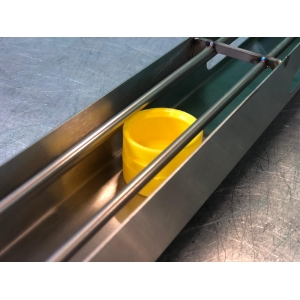

Bespoke Capping Solution for Food & Beverage Industry Customer

August 14, 2019

Bespoke Beverage Bottle Capping Solution

Adelphi Masterfil are creating a bespoke capping solution for an international client in the Food & Beverage industry.

Taking the widely loved Mastercap Indexing Capper as a starting point, the design has been modified to include a disc feeder to sort and orientate the unusual cap style, and a UV-lit cap feeder to decontaminate caps before they are placed onto containers.

Design Engineer Piotr Szymczak has put the UV feature into layman’s terms:

“With 60 caps per minute and 35 mm cap diameter, the speed of cap feeding is: 60 x 35 = 2100mm/min. The arc length of 44W fixture is 800mm, meaning you will achieve approximately 23 seconds of irradiation time on the caps. If we assume that the caps remain at a constant distance from the lamp for those 23 seconds, this would result in approximately 1414J/m2 of UVC energy delivered to the surface placed 60 mm away from the UV source”.

This is enough to achieve:

– 99.9% or higher kill rate of all common contaminants in the food industry (E.Coli, Listeria, Norovirus, etc.)

– Approximately 90% kill rate of the Aspergillus Niger (now called Aspergillus Brasiliensis) and an estimated similar level for other common moulds and yeasts. With an 86W lamp fixture, Piotr estimates that roughly a 99% kill rate of Aspergillus Niger would be achieved also.

This Bespoke Beverage Bottle Capping Solution both tests and shows off the capabilities of Adelphi Masterfil’s design and engineering department. Challenge them to meet your filling and capping needs today: call +44 (0)1444 472300 or email info@adelphi.uk.com