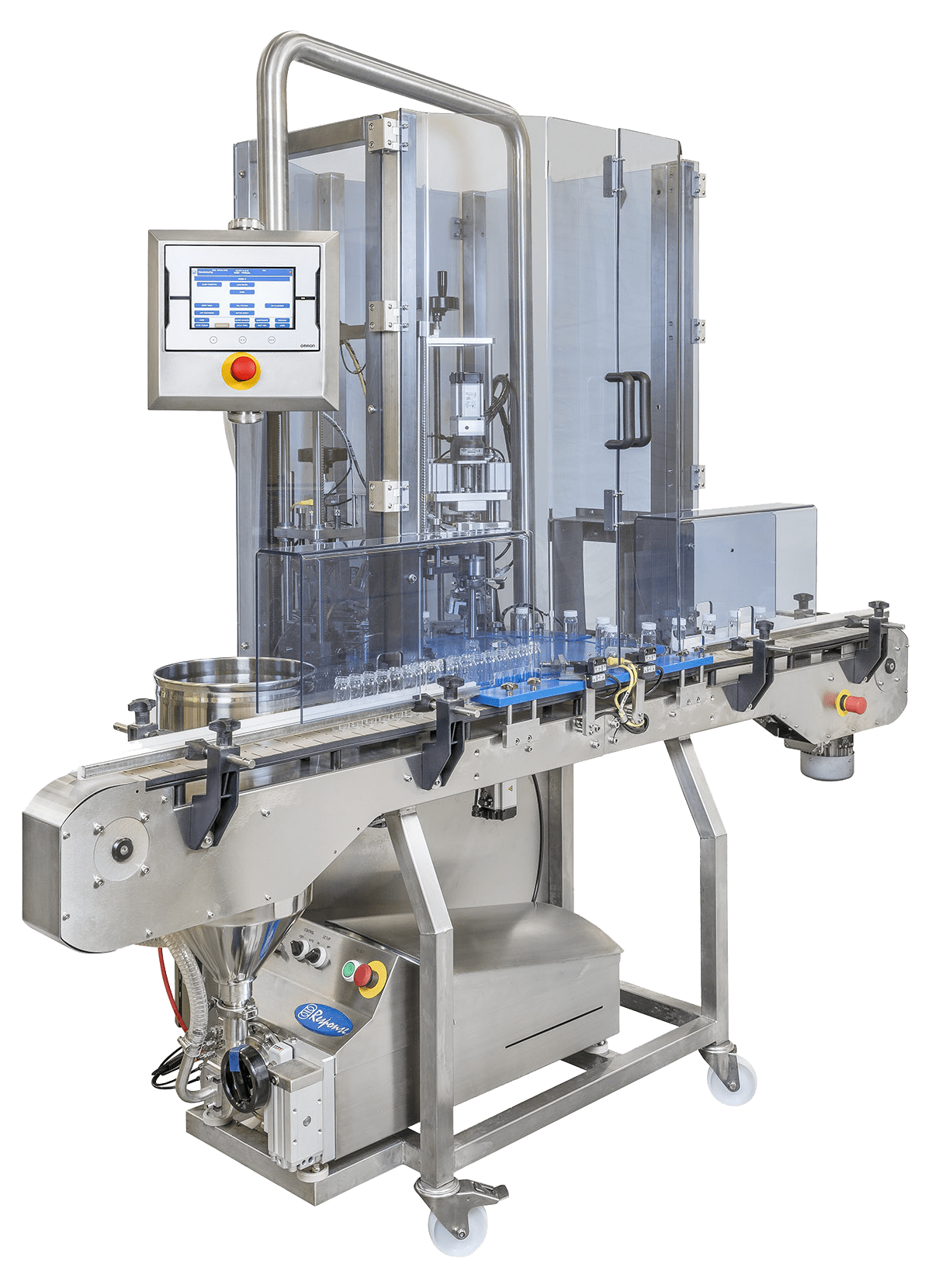

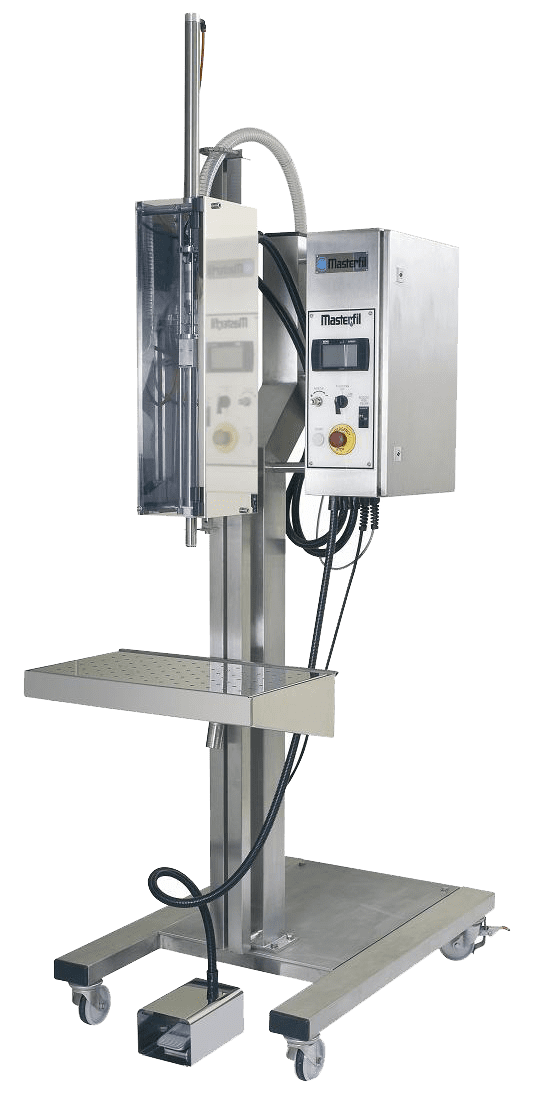

ATEX Response Benchtop Filler

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Delivery Within Days

Product Specification:

- CAT II B G c T 4 (135 Degrees Celsius) filling machine.

- Suitable for use in Zone 1 & Zone 2 applications.

- Made with ATEX certified pneumatic components.

- Well-engineered solutions to avoid static build up.

- Good earthing is ensured via an Earth Point at the rear.

- The hopper comes with a lid to reduce fume release.

- Various seal and O-ring options, which we will assess to ensure compatibility with your product.

- Fast filling, up to 40 containers per minute.

- Exceptional accuracy of up to ±0.25% reduces waste.

- Fill volumes from 3ml to 1L.

- Fully strip for cleaning in as little as 3 minutes.

- Versatile; interchangeable nozzles available for different products, including liquids, oils, gels, creams, pastes and thick products with particulates.

- Compliance peace of mind: we have lodged a technical file (09XT005) with an approved body.

Please note that our ATEX machines do not cover explosive risks from dust; only gas.

If your product does not require ATEX compliant machinery, the standard Response Benchtop Filler option would be the most cost-effective solution.

UK Manufactured: Zero EU Import Duty. Available from Stock (subject to availability)

UK Manufactured: Zero EU Import Duty. Available from Stock (subject to availability)

Contact us about this product

Case Studies

Luxury Whisky

Custom ATEX compliant Response Benchtop Filler reduces waste and improves cost-efficiency for luxury whisky manufacturer