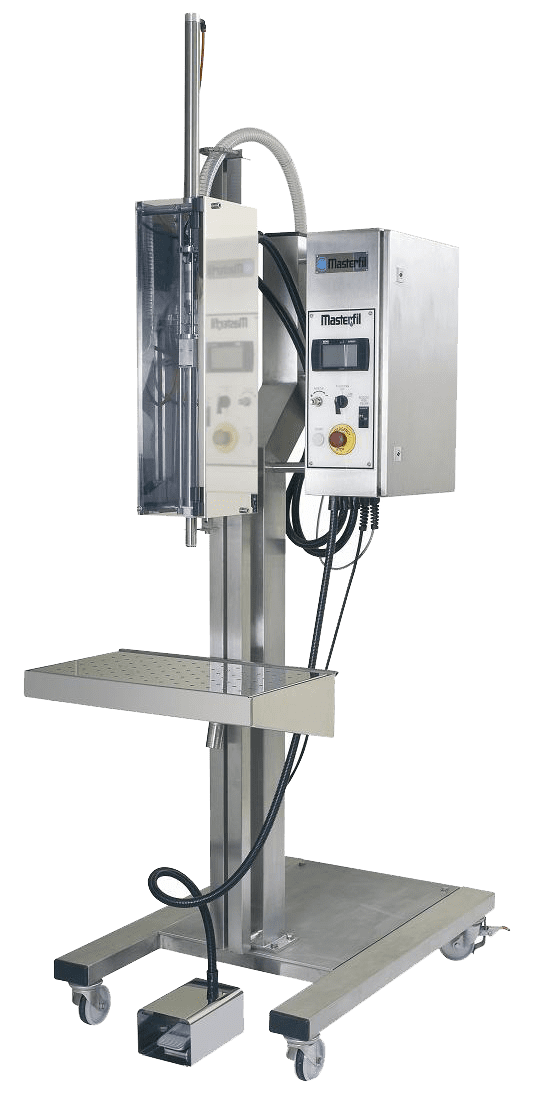

Masterfil Automatic Flowmeter Filler

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

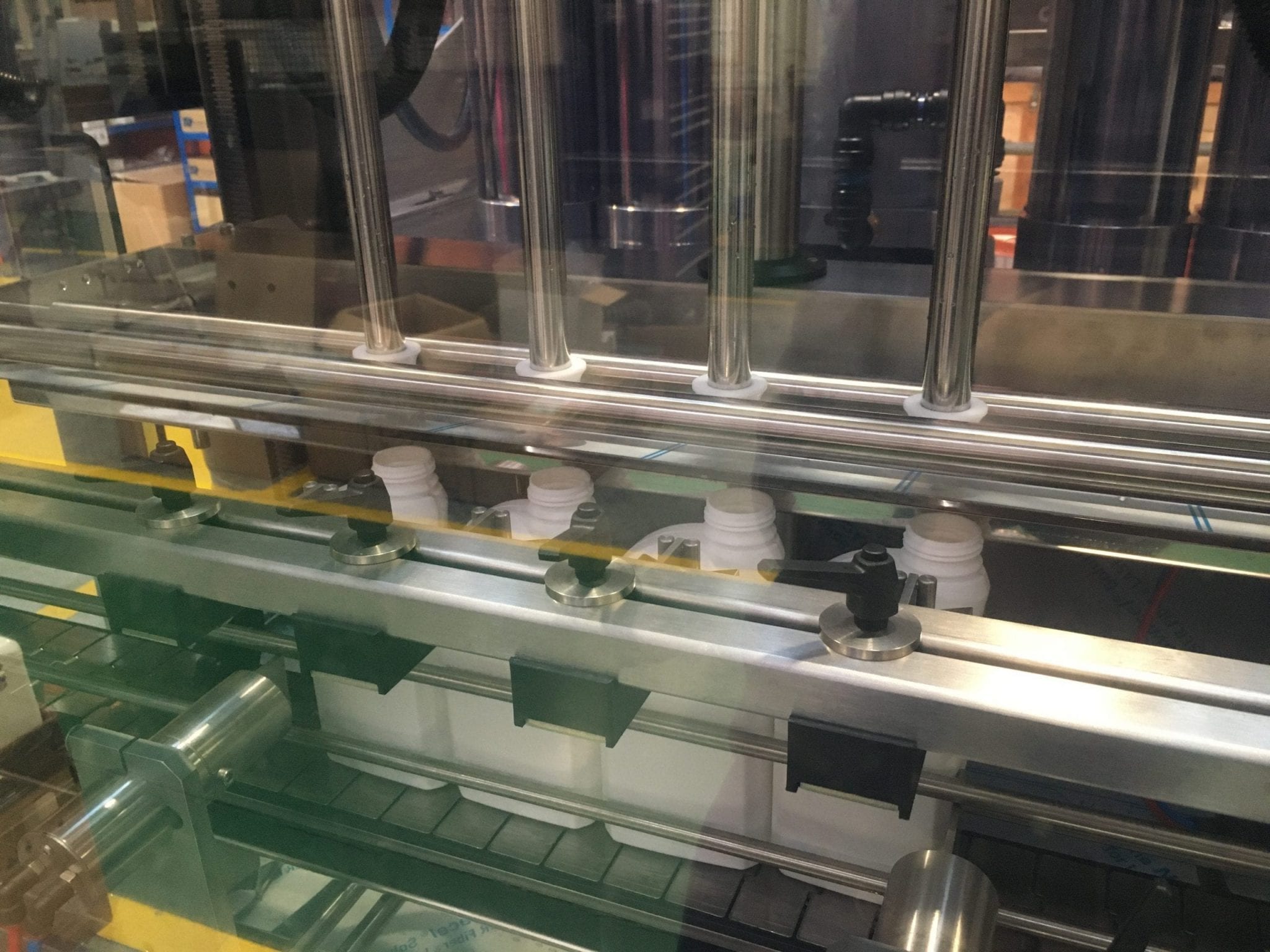

Up to 4,500 Containers per Hour

Product Specification:

- Fill volumes from 250ml to 30L.

- Exceptional accuracy of up to ±0.2% reduces waste.

- A choice of between 2 - 12 filling heads.

- Flexible; add extra heads to meet increased output requirements.

- Durable and robust, to endure the harshest environments.

- Versatile; nozzles are adjustable to fill foaming and non-foaming products with variable speed filling capacity.

- Minimal down time between liquid and container changeover.

- Storing multiple filling profiles increases efficiency on line throughputs.

- Easy recall of container fill profiles de-skills the machine operation.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

Please Note: This machine can be made ATEX compliant for flammable products.