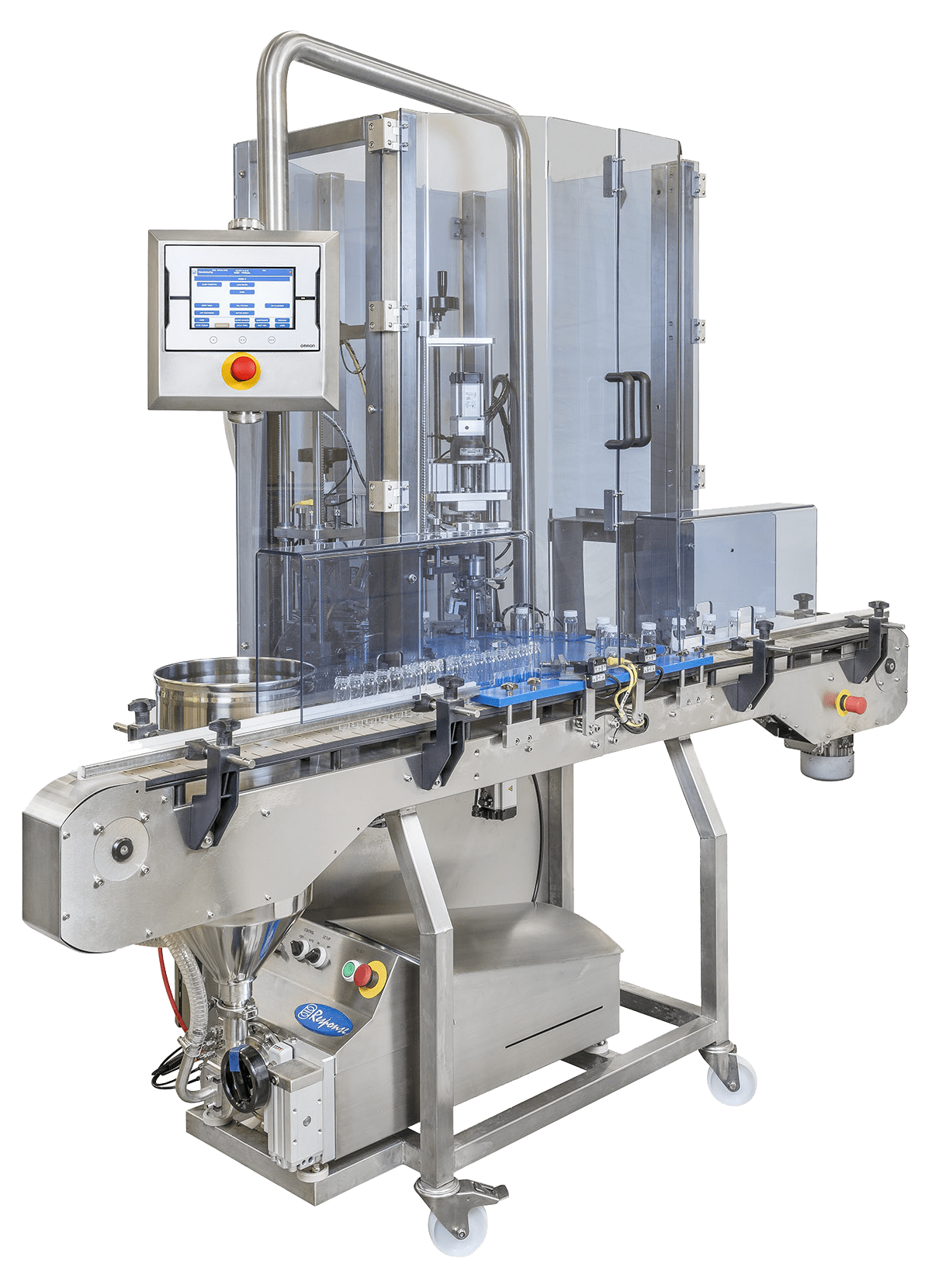

Response Monobloc 250 Filler & Capper

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Make the Most of Your Space

Product Specification:

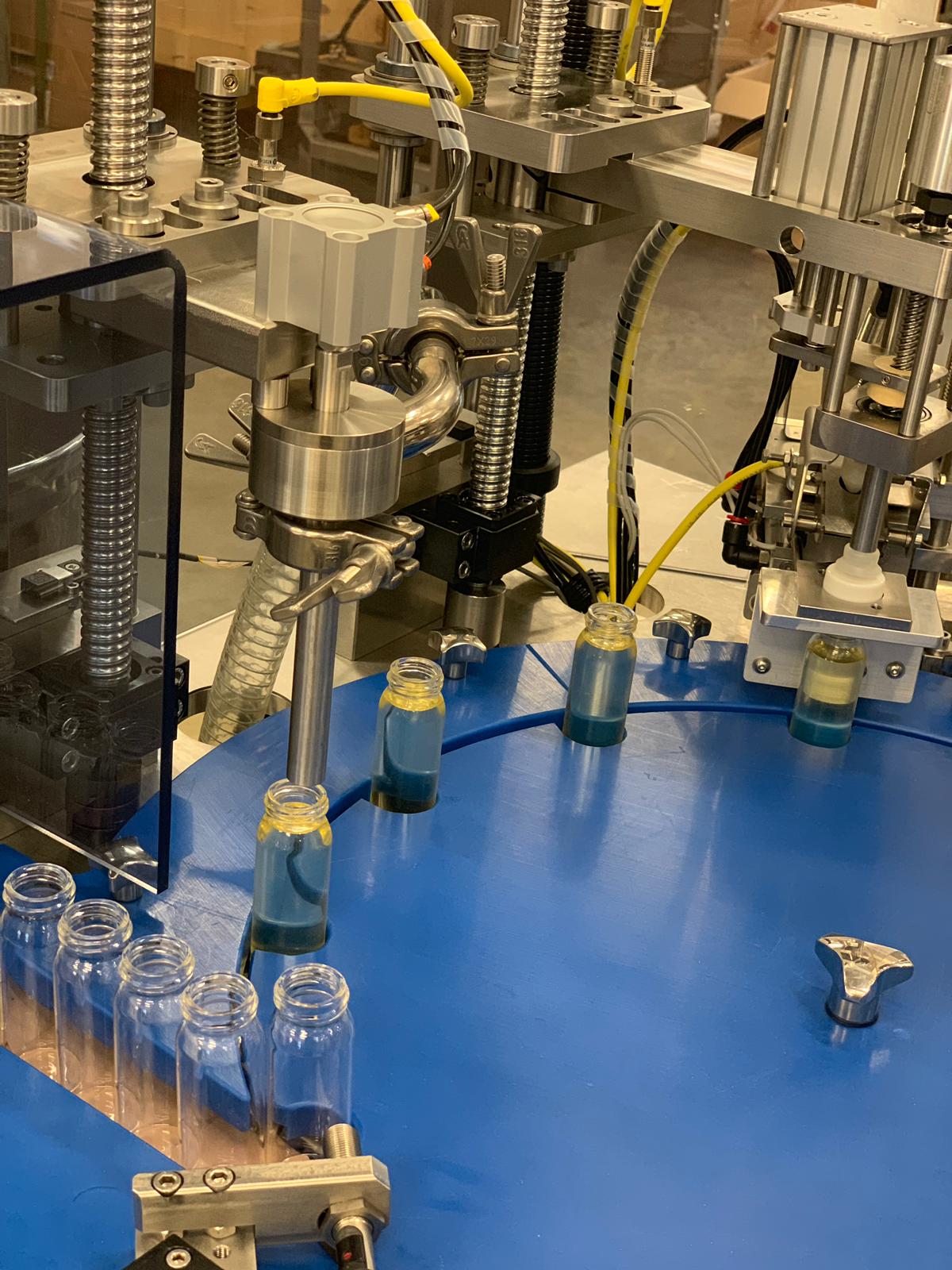

- Fast filling and capping, up to 35 containers per minute.

- Fill volumes from 3ml to 250ml.

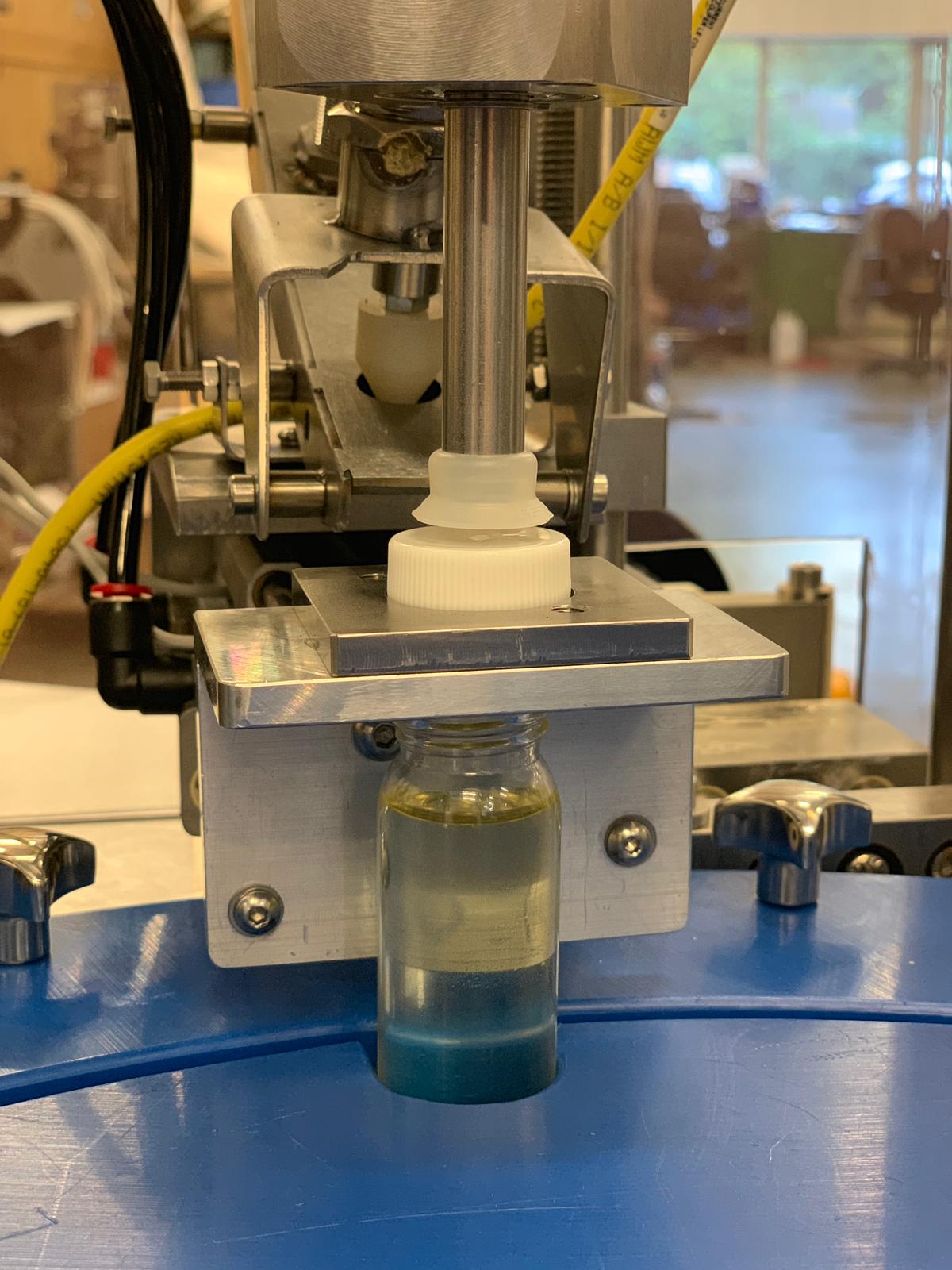

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Compact, space-efficient footprint.

- Fills bottles, jars and screw-top vials.

- Easy-to-use intuitive HMI touch screen controls for your operator.

- Quick and easy to change parts from one fill-size container to another.

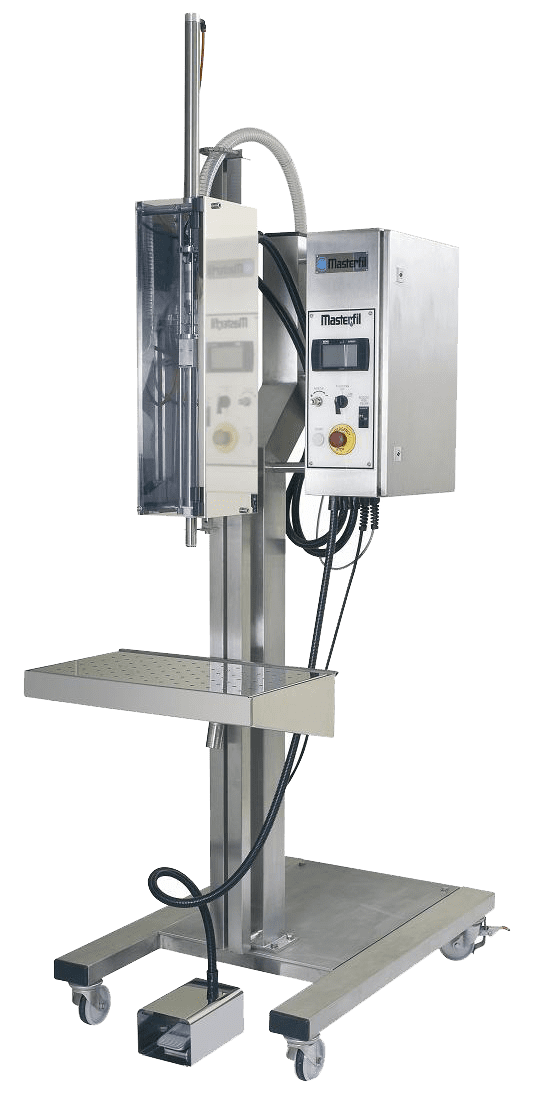

- Incorporates the Response Benchtop Filler, which can also be independently used if required.

Can include the following elements to give a complete turnkey packaging line:

In-feed table; Bottle blower; Filler; Automatic cap placement; Capper; Labeller; Collection table.

Adelphi Manufacturing also offer the

Response Monobloc 1000, for container sizes up to 1L.