News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

Securing Your Competitive Edge with Strategic Filling Automation

May 28, 2025

Why Strategic Filling Automation Partnerships Are the Future of Supply Chain Reliability for CMOs

In today’s increasingly volatile manufacturing environment, Contract Manufacturing Organizations (CMOs) face growing pressure to deliver speed, compliance, and flexibility whilst navigating complex and often fragile global supply chains. Amidst this uncertainty, the filling line is not just a production asset – it’s a critical aspect of your supply chain. Strategic partnerships with automation suppliers can unlock not only greater equipment uptime and throughput, but also long-term supply chain resilience. In this article, we explore how moving from transactional purchasing to collaborative, lifecycle-based partnerships is key to sustained competitive advantage.

The New Reality of Supply Chain Risk

Supply chains have always faced risk—but in recent years, those risks have accelerated and multiplied. From global health crises and geopolitical tensions to raw material shortages and labour constraints, CMOs are being asked to do more, faster, and with less room for error.

Within this pressure cooker, the reliability of core manufacturing assets – especially filling and packaging lines – can make or break your production schedule. A minor mechanical issue or parts delay can quickly escalate into missed delivery deadlines and dissatisfied clients.

The question isn’t whether your filling line works today—it’s whether it can deliver tomorrow, under pressure, and at scale.

The Higher Cost of a Reactive Supply Chain

If a single filling machine goes offline, the ripple effects are immediate and potentially costly: lost production hours, underutilised labour, compromised customer commitments, and potential regulatory headaches. Yet too often, CMOs maintain vendor relationships on a purely transactional basis, treating equipment procurement as a one-time event rather than a long-term value driver.

This reactive mind-set comes at a cost. It leaves CMOs exposed to unplanned downtime, inefficient support models, slow ramp-ups, and inflexible systems unable to adapt to new product demands.

Rethinking the Role of Filling Automation Suppliers

In this new landscape, it’s time to expect more from your machinery supplier.

A strategic partner does more than supply and install equipment—they help you design for resilience, scale for growth, and operate for consistency. They anticipate your needs before problems arise. They integrate deeply with your team to understand your production, compliance, and business objectives.

This is the new role of the filling automation supplier: a value-chain enabler who helps CMOs deliver reliable, secure, and flexible production to their brand-owner clients.

Reliability Begins at the Design Table

The foundation of supply chain reliability is laid long before a machine hits your production floor. It begins in how equipment is designed, configured, and tailored to your specific use case.

At Adelphi Manufacturing we work closely with CMOs during the early stages of capital investment to recommend filling systems that align with product diversity, batch sizes, cleanability requirements, and regulatory standards. Whether you’re working in pharma, personal care, food and drinks or nutraceuticals, your equipment architecture should anticipate your future – not just reflect your present.

When equipment is designed for modularity, rapid changeovers, and easy scalability, production becomes more agile – and far less prone to the kind of supply chain shocks we’ve all come to expect.

The Response range of scalable filling machines (recommended by the ECPA) offers:

- Fast changeovers between different products: fully strip for cleaning in as little as 3 minutes.

- Interchangeable nozzles to optimise filling of all your products, including liquids, oils, gels, creams, pastes and thick products with particulates.

- Exceptional filling accuracy of up to ± 0.25% (compared to the industry standard of ±1%) reduces waste from over-filling, and improves your profitability potential.

- The ability to increase production – semi to fully automatic – for a fraction of the cost (see below).

Lifecycle Support = Long-Term Security

Installation is only the beginning. Real supply chain security comes from what happens over the next 5, 15, or even 25 years.

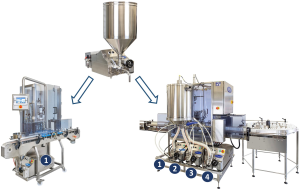

The Response filling machinery range enables your initial Benchtop Filler to grow organically to a fully automated solution – either Monobloc (with capping) or Inline style.

One Response Benchtop Filler (or Accuramatic Peristaltic Pump) can integrate into the Response Monobloc Filler/Capper. Centralising both filling and capping processes around a starwheel creates a significantly smaller footprint, ideal for premises with limited space.

Up to four Response Benchtop Fillers can be mounted onto the Response Automation Base, creating a fully automated inline filler with up to four heads. You can separate out one or all four of your benchtop machines again, for maximum flexibility, to fulfil multiple requirements at once.

The Response Automation Base also converts back again from an <4 head automatic filler into <4 benchtop filling machines within 10-30 minutes, depending upon how many machines you are separating. This is ideal to plan for an unexpected request or order coming in, or to fill samples, pilots or tightly controlled batches of high value products.

Beyond Equipment: The Value of Strategic Partnership

Too often, equipment procurement is handled as a series of disjointed transactions. But in a complex manufacturing environment, strategic partnerships consistently outperform one-off purchases.

When we engage as a long-term partner, we can:

- Anticipate your needs and proactively support expansion.

- Co-develop product-specific upgrades and features.

- Shorten lead times for parts and services.

- Provide fast-track support during audits or urgent campaigns.

This level of integration transforms your supply chain from reactive to resilient.

Case in Point: Adelphi Manufacturing was recently contacted by cosmetics and skincare CMO Mayfield Laboratories, to provide recommendations about refining operational processes, increasing filling efficiency and improving their overall flow and productivity.

During the visit, Adelphi’s Director Dean Willis was able to optimise fill speed potential, prevent unsightly air pockets in products, reduce product wasted through dripping, and improve the consistency of filling weights. For one notable cream product, throughput was increased from 16 bottles to 25 bottles per minute; over 500 additional bottles per hour!

Adelphi have provided “ongoing support as the business is growing,” says General Manager Lucy Poole. “If we’re bringing out a new product, we know we can ask your advice about how best to fill it – we can always pick your brain!”

Assistant Supervisor Julia adds: “you can rely on the Responses more than any other machine – you set the fill volume, and once you’ve got it there it stays there. They’re also easier to strip than any other machine we have.” Minimal downtime for stripping and cleaning is crucial, as Mayfield Laboratories fill batches of anywhere from 500 – 10,000, with their varied range of container and product types.

Let’s Secure the Future—Together

Supply chain security doesn’t begin with logistics—it begins on the production floor.

At Adelphi Manufacturing we believe the strongest CMOs are those who build strong partnerships – especially when it comes to core production technology. By working together from design to operation, we help our partners unlock long-term efficiency, scalability, and supply chain reliability.

“In the past year we have increased our product range by 20%…It does exactly what we were promised.

The main difference with Adelphi’s quality of service was the hands-on training we received. Adelphi offered to help us set up the machine, and stayed whilst we completed our first fills. It wasn’t just receiving a machine in a box, with no further support.”

Gary Conroy – Cosmetics CMO 5 Squirrels

If you’re ready to rethink your approach to filling automation, let’s talk. Together, we can build a smarter, more resilient future for your contract manufacturing operations.

+44(0)1444 472300 info@adelphi.uk.com