News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

Essential Oils: Your industry manufacturing guide

November 25, 2021

Essential oils are created from lipid compounds found in plants; they are typically of thick viscosity and therefore require equipment capable of the challenging product characteristics.

Adelphi’s Challenge:

To provide high quality, effective machinery and process equipment to ease operator pressure and increase productivity.

Adelphi’s Solutions:

Pharma Hygiene Products’ Water Jacketed Vessels:

- Durable, easy to sterilise and re-useable, for long service life and greater ROI.

- High level finishing – to an exceptional average surface finish of 0.4 micrometers Ra – leaves no pits or crevices for bacteria to store.

- 2 – 50L jacketed vessels available as standard.

- (other sizes available upon request)

- 316L pharmaceutical grade stainless steel, with a 304 food grade 0.1 bar low-pressure water jacket.

Pharma Hygiene Products’ High Shear and Propeller Mixers:

- Optional heated jackets for effective heating, cooling and maintaining temperature

- 304 grade stainless steel, with 316L pharmaceutical grade wetted parts, to guarantee no product contamination.

- Batch sizes from 20L to 100L (dependent on viscosity).

- Suitable for products with a viscosity up to 2,000cP (mPas).

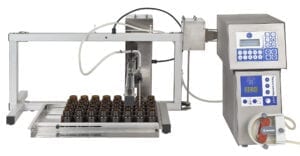

Adelphi Manufacturing’s XYZ Distributor and Accuramatic:

- Fills bottles, vials and nested syringes.

- Quick and efficient filling, up to 36ml per second.

- Exceptional filling accuracy of up to +/-0.5% reduces costly product waste.

- Infallible hygiene levels; the liquid only comes into contact with a length of silicone tubing, which will withstand repeated sterilisation. This produces a completely closed system, to eliminate the risk of cross contamination.

Adelphi Manufacturer’s Response Benchtop Filler:

- Fast filling, up to 30 tubes per minute.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Fill volumes from 3ml to 400ml.

Adelphi’s Benefits:

- One manufacturer, multiple solutions – all solutions will be manufactured on site with duties shared between sister companies (Pharma Hygiene Products & Adelphi Manufacturers)

- An award-winning, reliable supplier trusted by over 14,000 clients in over 110 countries for more than 70 years, quality is guaranteed through our ISO 9001:2015 certification

Don’t just take our word for it, you can read our testimonials and recommendations here >>>

Contact us on +44 (0)1444 472 300 or email info@adelphi.uk.com