News Blog

Keep up to date with the latest news, insights and features from the Adelphi Group of Companies

Bespoke ATEX filling solution for luxury whisky

September 9, 2020

ATEX Filling for Whisky

Multinational whisky manufacturer reduces waste by 300% with custom Adelphi Filler

THE CHALLENGE:

ATEX Filling for Whisky: A premium product requires a premium solution – waste could potentially cost our customer, a multinational whisky manufacturer, thousands of pounds in a single year.

“In early 2018 our luxury production area had a request to fill very low volume but very high value products, which would require accurate manual filling, with the need to keep the product integrity to the highest specification. Due to the strength of these products it was important that any filling equipment sourced would comply with strict criteria and compliances, including ATEX, DSEAR, SIL, PUWER and manual handling.”

THE SOLUTION:

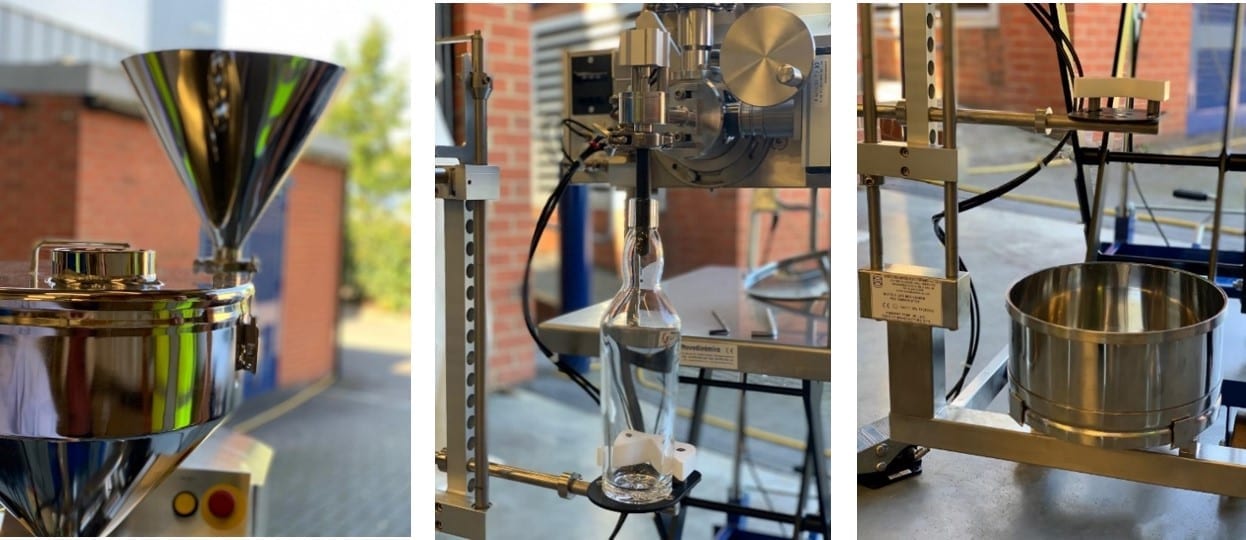

Adelphi supplied a custom ATEX Zone 1 Category IIB 2G c T5 (100C) compliant Response Benchtop Filler, which boasts exceptional filling accuracy of ± 0.25% (far superior to the industry average of ± 1%). In terms of industry average fill accuracy alone, this reduces waste by 7.5L out of every 1,000L filled (10L to 2.5L – a saving of 300%). 316L pharmaceutical grade stainless steel construction guarantees the highest possible levels of hygiene; avoiding contamination of this superior whisky.

“Adelphi arranged for us to have a trial unit to test the Response machine’s filling accuracy and capabilities.

We were given the opportunity to work closely with Adelphi through all steps of the build, to achieve the full scope of requirements specific to our needs; together we built a bespoke version of the Response Benchtop Filler to fulfil our exact brief.”

Zero waste

Two-speed gentle filling ensures no splash-back, and hygienic drip-trays catch any wayward droplets. Whisky is an even lower viscosity liquid than water, but double PTFE seals on the three-way valve guarantee no leakage when feeding the whisky from the hopper. An additional 6L hopper drains into the main 20L hopper, with a gauze filter between the two to ensure no contaminants – such as oak from the whisky barrel – can get through. This product only ever reaches the customer meeting the required quality standards.

“Having a stand-alone ATEX rated filling machine was a real USP; as was the opportunity to bespoke-design the unit to meet our operational, safety and compliance needs.”

Quick to strip and clean – less costly production downtime

Full strip-down of the Response Benchtop Filler for cleaning can be achieved in 3 minutes! Many customers keep a spare set of wetted parts, so that changeover between products can be as quick as possible.

Unsurpassed hygiene

Critically for ingestible products such as beverages, all parts which come into contact with the whisky on the Response Benchtop Filler are manufactured in 316L pharmaceutical grade stainless steel, PTFE and Viton. Curved and sloping surfaces meet GMP requirements. Clean, lubricant-free pneumatics and sanitary tri-clamp hopper connections prevent unhygienic build-up of residue. The bespoke filling nozzle was also PTFE coated to protect against damage to the glass bottle neck – maintaining the immaculate finish.

Improved employee health and happiness

Feeding product into a filling machine can sometimes mean a tricky angle and height of lift for operating staff, and this presents some ergonomic challenges. However, this solution included a pneumatic trolley that supports the filler, which is lowered to a good working height when the hopper needs filling.

“Based on the performance of the Response filling machine, and the experience of working with Adelphi’s technical team on the bespoke design, we would recommend Adelphi to other suppliers.”