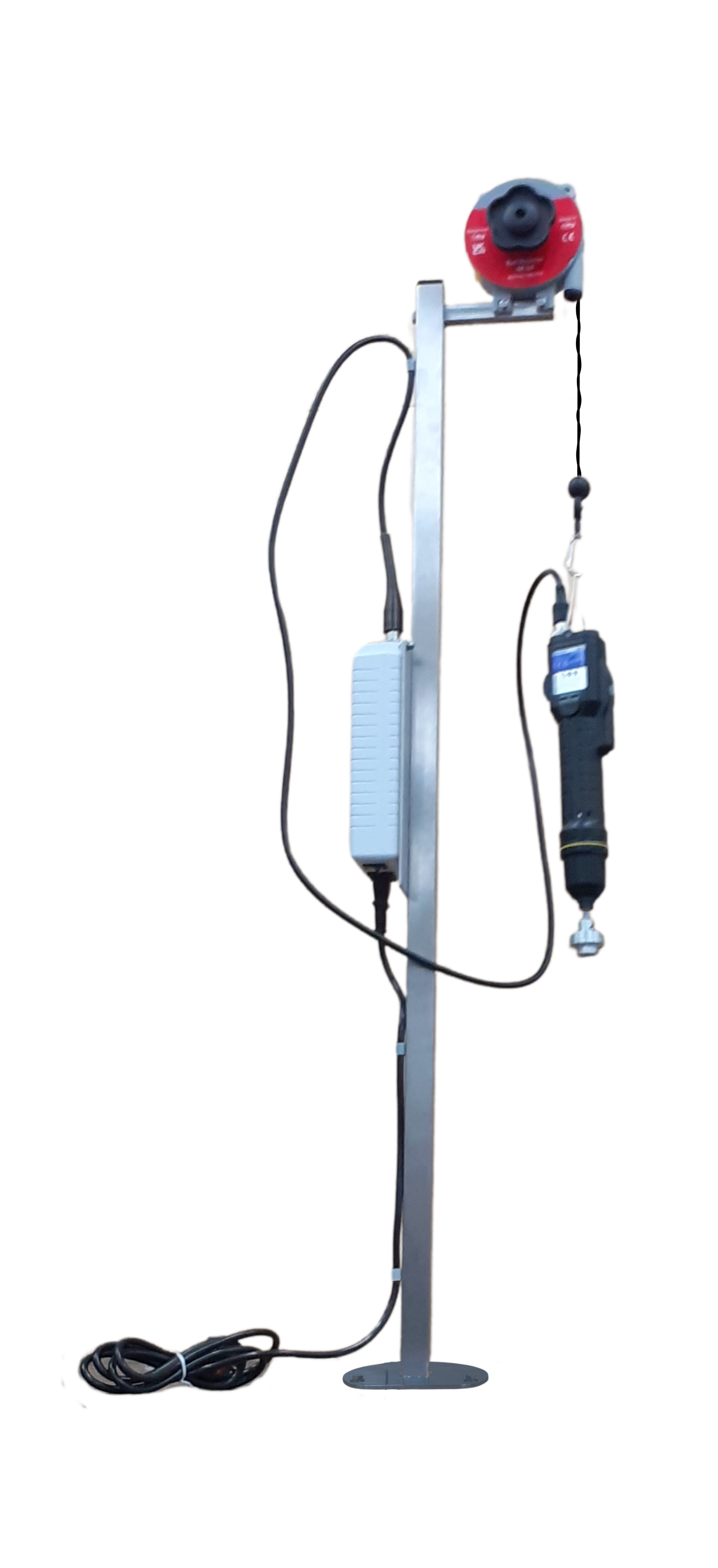

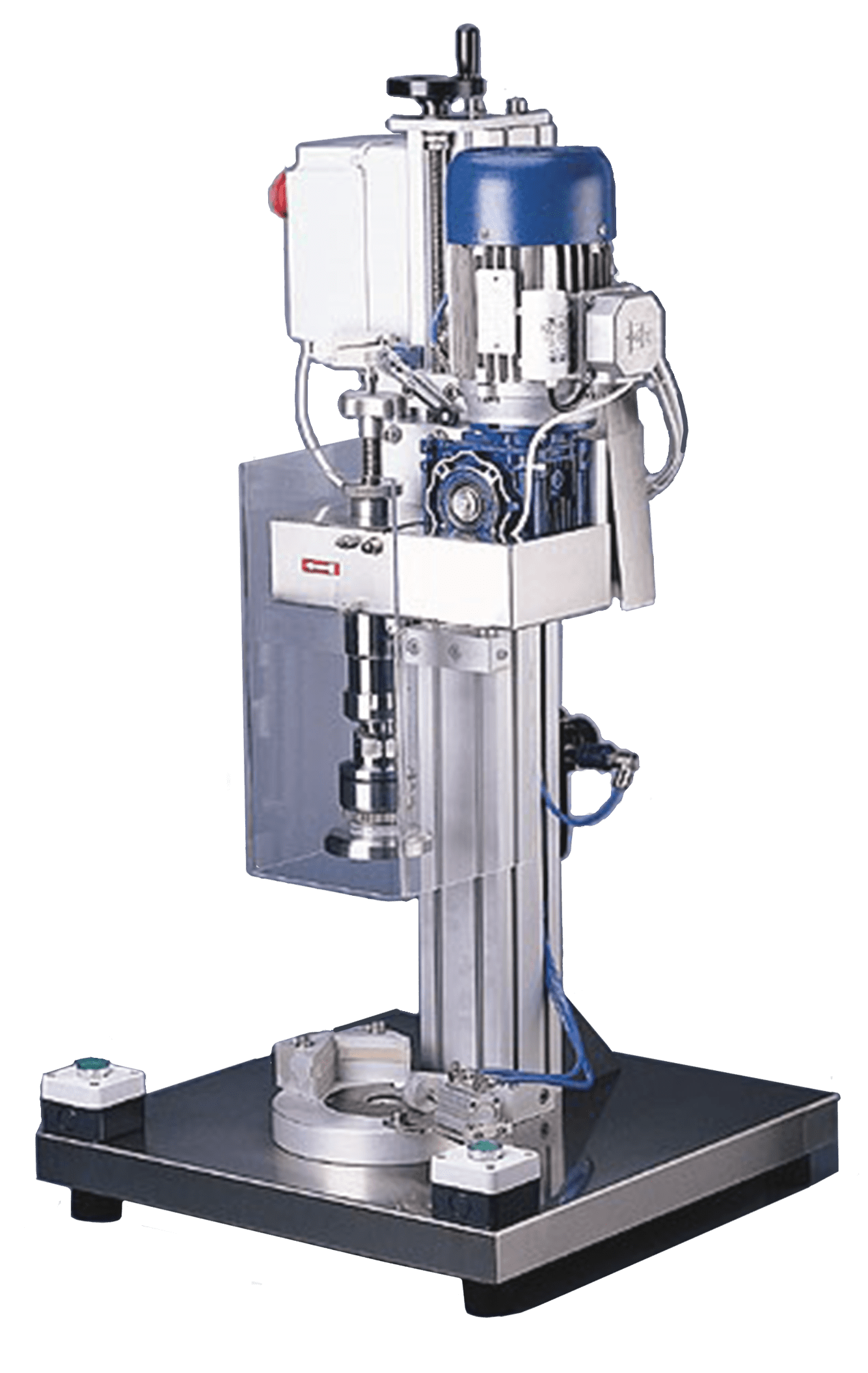

Benchtop Screw Capper

Quick, Efficient & Adaptable

Simple & Intuitive to Use

Fits a Wide Range of Cap Sizes

Product Specification:

- Adjustable torque control on capping head via magnetic clutch from 0.2 Nm to 2 Nm.

- Mains Power req: 240v, single phase, 50Hz, 0.25hp

- Compressed air req: 5 Bar/1cfm

- Weight: 40 Kg

- Size: 500 x 500 x 1000mmh

- Min/Max bottle height: 20/350mm

- Min/Max bottle diameter: 5/200mm

- Max cap diameter: 110mm

- Includes a fully adjustable height using a hand wheel, electrical panel with emergency stop and isolator, bottle locator and anti-rotation bottle lock, safety guards and safety start buttons.

Contact us about this product

Adelphi Capping Machines

From manual, handheld closing options to semi-automatic and fully automatic machinery, Adelphi have a solution to suit all types of budgets, containers and customer requirements.

Browse our manual capping and closing options:

- Twin jet

- Syringe stopper press

- Manual bottle cap press

- Manual vial crimper

- Crimping tongs

From manual, handheld closing options to semi-automatic and fully automatic machinery, Adelphi have a solution to suit all types of budgets, containers and customer requirements.

Browse our manual capping and closing options:

- Twin jet

- Syringe stopper press

- Manual bottle cap press

- Manual vial crimper

- Crimping tongs

Browse our fully automatic capping and closing options:

- Indexing Capper

Semi-Automatic Capping Machinery

Semi-automatic capping refers to any capper machine where the operator must place the container under the capping head and press for capping, rather than an automatic capping machine that will use a conveyor.

Pneumatic Capping Machine

The Adelphi Pneumatic Capping Machine is a bench top unit suitable for closing twist-off caps easily and with great accuracy. It is robust yet portable, very easy to operate, and low maintenance.

The machine is adapted to a wide range of cap sizes by changing only the cap chuck. Strong and reliable, this capper allows the operator to close around 400 – 500 bottles per hour.

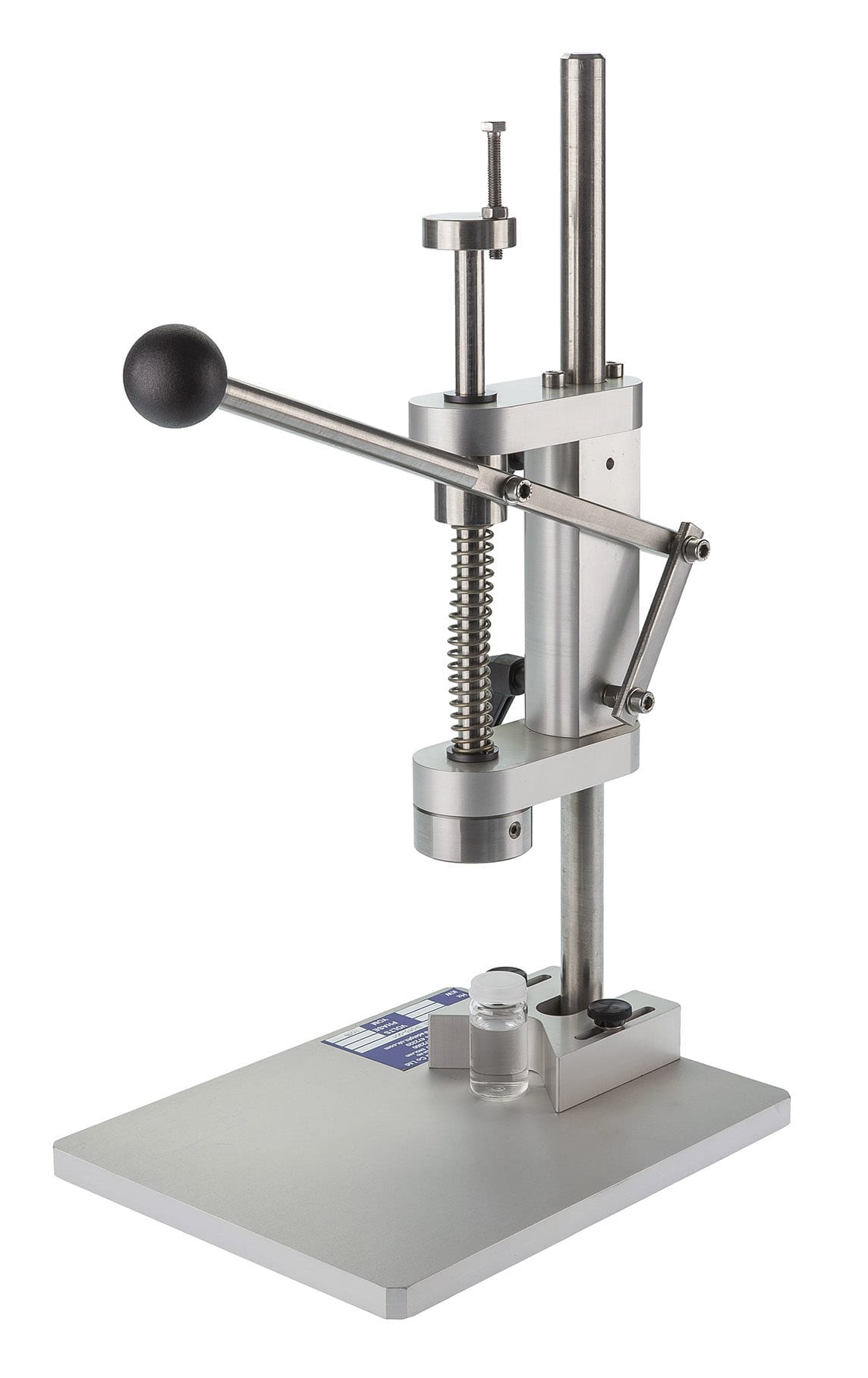

Adelphi ROPP Capping Machine

The Adelphi ROPP Capping Machine is a bench top machine for applying aluminium ROPP caps. The unit is fully adjustable in height using a hand wheel, and includes an electrical control panel with emergency stop and isolator, 4 roller capping head, bottle locator, and safety guard and safety start buttons.

Automatic Capping Machines

The Mastercap Indexing Capper is a cost-effective solution, which can help you reduce waste and increase throughput, to improve your ROI.

Some of the benefits include:

- Superior Build Quality, Longer Service Life, Greater ROI – many of our machines are still fully operational over 30 years after purchase!

- Versatile Applications – Ideal for Screw caps, Press on caps, Tamper proof caps, Sports caps, Aerosol overcaps, Angled neck containers and Inserts.

- Time Efficient, Fast Capping – Up to 60 caps per minute; perfect for capping containers up to 25L.

- No container, no cap and queue sensing, to reduce waste and increase throughput.

- Optimum Hygienic Design – Cap sterilisation option, using UV light on the cap feed chute.

Manual Capper Machine

Manual capping and closing is ideal for smaller manufacturers who aren’t yet ready to take the plunge into automation. Adelphi Manufacturing offer a range of hand operated capping machines to support our customers at all stages.

All of our cappers are constructed from hygienic and durable stainless steel for a long service life. Adelphi have a range of manual closing options to suit a variety of container types:

Tube folding pliers provide a simple method of reliably closing individual metal tubes. They are hand held with plastic handles for comfort and safety. They are suitable for metal tube diameters 12-40mm.

ROPP Capping Machines

Capping is a fundamental part of many manufacturing processes, and one where seemingly minor issues can add up to a serious productivity problem.

Simple automation solutions can help:

- Reduce variances in torque tightness, which also reduces your time repeat-handling quality rejects

- Minimise the risk of repetitive strain injury, and improve job satisfaction

- Speed up your overall production, for greater output and greater profit!

The ROPP Capper machine is a benchtop machine for applying aluminium ROPP caps.

- Simple and intuitive to use – get started right away

- Versatile design fits a wide range of cap sizes

- Fully height adjustable for operator safety and comfort

Explore Our Range of Capping Machinery today

Browse our full range of closing and capping machines.

You can filter by container type and size to find the perfect solution for you.

If you would like to receive expert advice on the best filling machine for your business, contact us using the form below